Metal Fabrication

Conveyors for Metal Fabrication

From coil to finished part, Bunting delivers integrated magnetic solutions and conveyor systems purpose-built for the demands of metal fabrication operations. Whether you’re working with ferrous or mixed-metal stock, our solutions help manage scrap, protect equipment, and ensure efficient, uninterrupted production.

Our systems are used in metal fabrication environments to:

- Remove slugs, scrap, and tramp metal from die areas and part flow

- Protect dies, feed lines, conveyors, and downstream equipment

- Prevent misfeeds and double-sheet faults in automated systems

- Improve scrap separation for recycling and material recovery

- Support safe, continuous part and scrap handling throughout production

Safeguarding Equipment and Maximizing Uptime

Tramp metal and slug build-up can severely damage fabrication dies, misalign feed stock, and halt production. Bunting’s magnetic and conveying solutions are engineered to remove and control metal debris in fast-paced fabrication environments—ensuring continuous operation and extending the life of your equipment.

Total Scrap Handling & Protection Solutions

We offer a complete range of systems for metal fabrication operations—whether you’re handling stainless coil, aluminum blanks, or galvanized parts. Our solutions reduce unplanned downtime, improve material cleanliness, and streamline safe scrap handling from press to bin.

Solutions

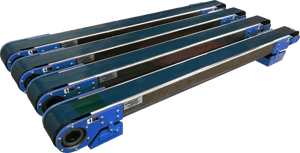

Bunting offers a full range of heavy-duty, magnetic, and precision conveyor solutions engineered specifically for the demands of metal stamping operations. Whether you're moving ferrous scrap, feeding sheets into presses, or retrieving small stamped parts, our conveyors are designed to maximize uptime, improve scrap flow, and protect your pressroom investments.

Our stamping conveyors are used to:

- Transfer ferrous chips, slugs, and turnings from under presses and machine tools

- Feed and orient metal blanks into presses, welders, or shears with exact timing

- Retrieve small ferrous parts from vibratory bowls, finishing stations, and sorting lines

- Handle scrap and parts in tight spaces with low-profile, gang-driven configurations

- Eliminate jams, reduce maintenance, and streamline material flow throughout your facility

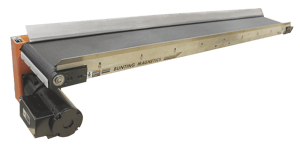

Magnetic Sheet Fanners

Magnetic sheet fanners safely separate oily, sticky, or polished ferrous sheets to eliminate misfeeds and double-sheet errors in automated press lines. Available in multiple configurations—including switchable, machine-mounted, pivoting, and retractable pin styles—these fanners enhance line efficiency and reduce downtime during high-speed stamping operations.

Aerosol Test Bath Magnetic Rails

Designed for maximum magnetic hold-down during aerosol can testing, these custom-engineered magnetic rails are available in single or dual-lane chain configurations. Built to suit your tank, chain, and application requirements, they deliver stability and precision throughout the testing process.

Magnetic Plate Rails

Engineered for use in horizontal and inclined mat-top or fabric belt conveyors, our magnetic plate rails provide powerful part control in washdown or wet stamping environments. Constructed with the strongest magnetic rails in the industry, they ensure reliable product positioning and smooth material flow through transfer and inspection zones.

Products

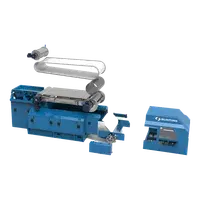

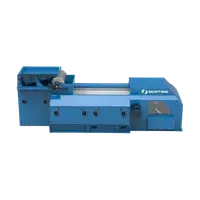

Bunting offers a comprehensive range of magnetic and engineered conveyor systems built to meet the rigorous demands of industrial material handling. Whether you’re moving scrap from a high-speed stamping press, transferring battery cells in a recycling facility, our conveyors deliver superior performance, reliability, and integration flexibility.Fully enclosed magnetic scrap conveyors ideal for ferrous material transfer in metal stamping, machining, and battery processing applications.

Flexible magnetic conveyors used to collect small stamped or formed parts from finishing equipment or robotic cells.

Designed to feed and orient sheet metal or battery plates into presses, welders, or shears with high positional accuracy.

Built for under-press, gang-driven, or space-limited installations where compact form and durability are critical

Metal Fabrication Equipment

Move and control ferrous scrap, parts, and chips from presses and metalworking machinery with powerful, maintenance-free magnetic conveying.

Efficiently remove ferrous parts from vibratory bowls and finishing systems, supporting automated and flexible part handling.

Moves magnetic and non-magnetic manufactured parts from point A to point B

Compact conveyors designed for tight spaces under presses or automation systems, delivering reliable performance for a variety of part sizes.

Precisely convey, stack, or de-stack sheets of various sizes into and out of presses, welders, and shears for seamless integration with automated lines.

Pry apart oily, sticky, or pre-finished ferrous sheets for easy, automated feeding-available in switchable, permanent, pivoting, and retractable styles.

Easy-to-install components that deliver years of reliable service, available in a variety of sizes and magnetic strengths for demanding applications.

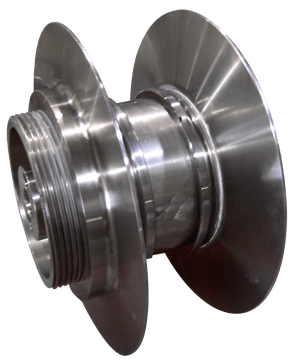

Variable speed magnetic pulleys for fanning, stabilizing, and feeding lids or sheets into sleeves or feeding machines-ideal for canning and packaging.

The smart solution for fast, powerful cleanup of ferrous metal contamination.

Our Magnetic Test Bath Rails are designed and manufactured for either a single or a dual lane chain for maximum hold down and are engineered and designed for your tank, your chain and your application.

FAQ's

A: Bunting provides magnetic conveyors, sheet fanners and magnetic tooling equipment designed to improve safety, efficiency, and uptime in stamping and fabricating environments

A: Magnetic conveyors like Bunting's MagSlide® systems are ideal for transporting oily metal scrap, chips, and small stamped parts without jamming. They offer enclosed construction with no external moving parts, reducing maintenance and improving safety.

A: MagSlide® conveyors handle abrasive, jagged scrap that can damage traditional conveyors. With fully enclosed drive systems and powerful magnets, they require minimal maintenance and are built for rugged, continuous useBunting-Metal Working I….

A: Bunting offers horizontal, incline, and nose-over magnetic conveyor configurations, with add-ons like manganese slider beds, mobile bases, and hoppers to fit your facility’s layout.

A: Yes. Bunting provides magnetic timing belt transfer conveyors and magnetic stackers that orient and stack stamped parts accurately for downstream processing or packaging.

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.