Suspended Electromagnets

| Magnet | Electromagnetic coils |

| Working gap | Up to 800mm (32") |

| Material | Dry bulk |

| Separates | Ferrous |

Options

Superior heat dissipation ideal for harsh environments. ATEX versions available.

Simpler design with lower initial cost. Suitable for lighter-duty applications.

A compact, high strength, air-cooled electromagnet.

Animation

- About

- Benefits

- Tech Specs

Industries: Aggregate, Mining, Biomass, Minerals, Recycling, Plastics, Food & Pharma, Ceramics, Auto Shredding, Metal Stamping & Fabrication

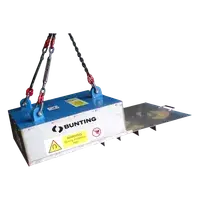

The Bunting Electro Suspended Magnet, also known as an electro suspension magnet, has been a cornerstone in various industries for decades, playing a crucial role in ensuring product purity and operational efficiency. Specifically designed to remove large ferrous contaminants from bulk materials on conveyor belts, this powerful magnetic separator is essential for protecting downstream equipment and maintaining product quality in industries such as mining, recycling, and aggregate processing.

The Electro Suspended Magnet features a robust electromagnetic coil that generates a strong, deeply penetrating magnetic field capable of capturing and holding even large tramp metal objects. This powerful system effectively removes ferrous contaminants from deep burden depths and high-speed conveyor belts, offering superior protection against equipment damage and product contamination.

Constructed with a durable steel housing and available in both oil-cooled and air-cooled configurations, the Bunting Electro Suspended Magnet is designed for seamless integration into existing processing lines. Its ability to be switched on and off allows for easy cleaning and flexible operation, reducing maintenance time and enhancing productivity. This versatile magnetic separator can be customized to accommodate various conveyor widths and material depths, making it the ideal solution for industries dealing with high-volume material handling and seeking to improve product quality and equipment longevity.

Effective Ferrous Contaminant Removal: Efficiently captures and removes ferrous materials, preventing damage to downstream equipment and ensuring product purity.

High Magnetic Strength: Generates strong magnetic fields, capable of attracting large tramp metal and small ferrous particles from deep material depths.

Energy Efficiency: Operates without continuous power consumption; can be switched on and off as needed, reducing energy costs.

Durable Construction: Built with robust steel housing, designed to withstand harsh industrial environments for long-lasting performance.

Flexible Installation: Customizable suspension heights and widths allow for easy integration into existing conveyor systems and various applications.

Oil-Cooled or Air-Cooled Options: Available in both cooling configurations to suit different operational needs and environmental conditions.

Versatile Applications: Suitable for a wide range of industries, including mining, recycling, food processing, and construction, enhancing operational efficiency across sectors.

Improved Product Quality: Ensures contaminant-free products, helping companies adhere to safety standards and maintain customer satisfaction.

Process Equipment Protection: Protects expensive machinery from damage caused by ferrous contaminants, reducing repair costs and downtime.

Magnet Type

Electromagnetic coils (copper or aluminum windings)

Materials Handled

Suitable for conveyed bulk materials

Belt Width

Available for conveyor belts up to 2400mm (96")

Suspension Height

Up to 800 mm (32")

Cooling Systems

Oil-cooled and Air-cooled

Housing Material

Heavy-duty steel construction with a manganese baseplate

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.