Stainless Steel Separators

| Magnet | Rare Earth Magnetic Roll |

| Material Size | Particle sizes from 5-125mm (1/4"-5") |

| Separates | Stainless Steel |

Options / Features

Enhance material flow by using controlled vibrations to ensure consistent movement and prevent clumping.

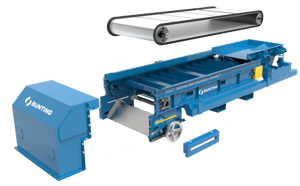

Patented high-intensity neodymium magnetic circuit head pulley.

Adjust belt speed for optimal separation.

Animation

- About

- Benefits

- Tech Specs

- Models

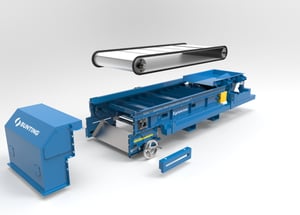

Bunting's Stainless Steel Separator stands at the forefront of metal recovery technology, delivering unparalleled performance and operational efficiency. Specifically engineered to separate stainless steel from mixed waste streams, this advanced separator maximizes material recovery and enhances the overall recycling process. It features powerful rare earth magnetic systems that effectively extract even the most challenging metal particles, providing superior separation capabilities across various industrial applications.

Constructed with robust materials and a cutting-edge design, the Bunting Stainless Steel Separator seamlessly integrates into existing recycling and processing lines. Its versatile configuration allows for easy customization to meet specific operational requirements, enhancing productivity in diverse applications.

This high-performance separator accommodates various material sizes and handles a wide range of waste streams. It is the ideal solution for recycling facilities and manufacturers aiming to optimize metal recovery processes while adhering to stringent environmental standards.

Powerful Separation: The Stainless Steel Separator effectively extracts stainless steel from mixed waste streams, maximizing material recovery.

Versatile Application: Capable of handling various particle sizes, up to 125mm (5") in size, making it suitable for a wide range of recycling and industrial processes.

Robust Construction: Built with durable materials to withstand demanding industrial environments, ensuring long-term reliability and performance.

Advanced Technology: Utilizes rare earth magnets and optimized rotor configurations to achieve superior separation efficiency across different material types.

Easy Integration: Seamlessly integrates into existing recycling and processing lines, enhancing overall system efficiency.

Environmentally Friendly: Supports sustainable practices by recovering valuable metals that would otherwise be discarded, reducing waste sent to landfills.

Industries

Recycling, plastics

Magnet Type

Rare Earth Magnetic Roll (Neodymium)

Magnetic Strength

Ultra-high intensity, capable of attracting weakly magnetic materials

Materials Handled

Particle sizes from 5-125mm (1/4"-5")

Pulley Diameters

150mm (6")

200mm (8")

300mm (12")

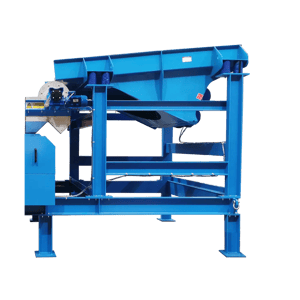

Conveying System

Vibratory feeder for controlled material flow

Conveyor belt with tough urethane construction

Frame Construction

Heavy-duty 5mm frames

Stainless steel discharge ends to prevent magnetic inducement

Separation Targets

Stainless steel with slight magnetic properties

Performance

Capable of extracting up to 94% of large fraction stainless steel and up to 98% of small and mid-fraction stainless steel

Bunting offers two high-performance Stainless Steel Separator models, each designed to meet specific separation challenges:

HISC™ - Stainless Steel Separation Conveyor

- Handles material sizes as small as 5mm (1/4")

- Ideal for recycling, WEEE processing, and various industrial applications

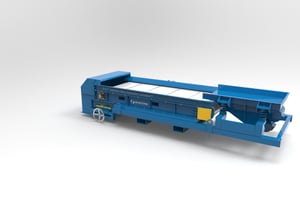

SSSC™ - Stainless Steel Separation Conveyor

Developed to separate larger fragmented stainless steel.

- Handles materials up to 125mm (5") in size

- Designed for high-volume, continuous operation in large-scale recycling facilities

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.