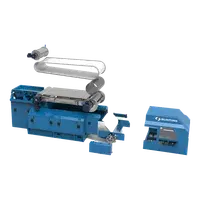

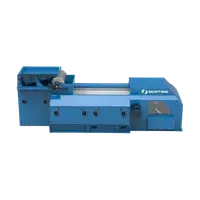

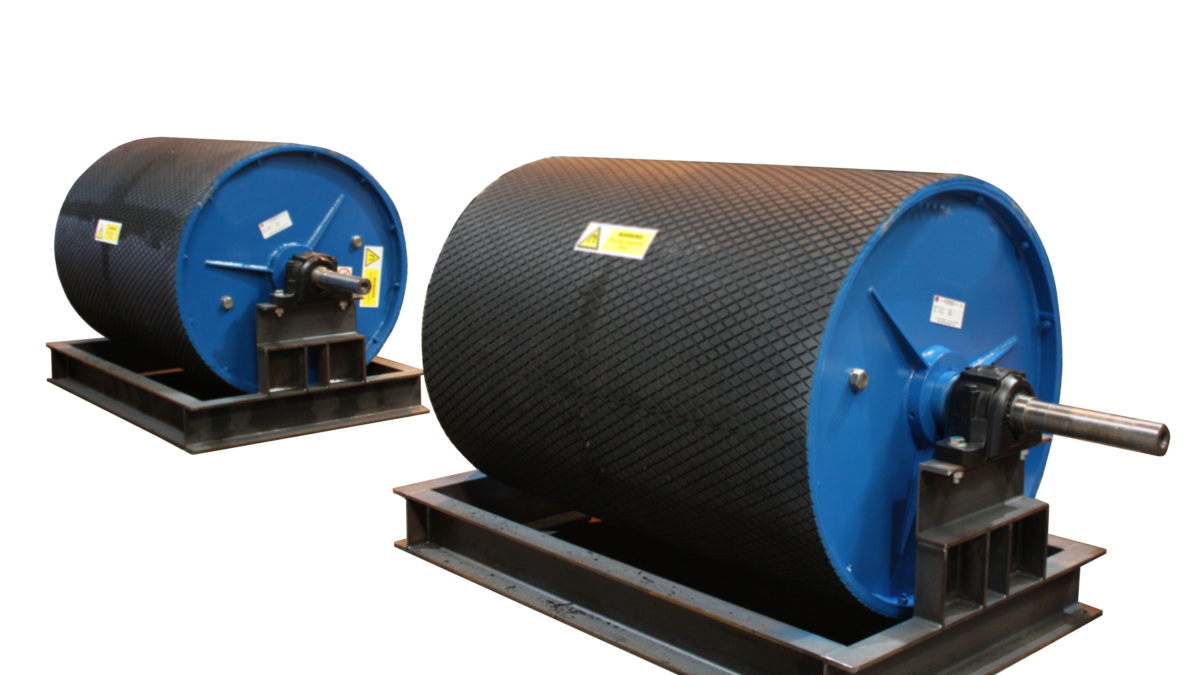

Magnetic Head Pulleys

| Magnet | Ceramic, Rare Earth or Electro |

| Material | Bulk materials |

| Separates | Ferrous contaminants, tramp metal |

Options / Features

Ceramic, rare earth or electro magnets deliver powerful fields for effective ferrous metal separation

Robust design withstands harsh industrial environments with minimal maintenance.

Seamlessly integrates into conveyor systems, protecting equipment and improving product purity.

Animation

- About

- Benefits

- Tech Specs

Magnetic Head Pulleys are innovative solutions designed to efficiently remove ferrous contaminants from bulk materials in various industrial processes. These powerful separators integrate into existing conveyor systems, offering a compact and effective method for metal extraction.

At Bunting, we leverage decades of magnetic engineering expertise to produce high-performance Magnetic Head Pulleys. Our range includes both permanent magnet and electromagnetic options, catering to diverse operational needs across industries such as recycling, mining, food processing, and bulk material handling.

Our permanent magnet pulleys utilize either ceramic or rare earth magnets, providing consistent magnetic strength without the need for external power. For applications requiring adjustable field strength, our electromagnetic pulleys offer precise control and enhanced separation capabilities.

Engineered for durability and minimal maintenance, Bunting's Magnetic Head Pulleys ensure long-term reliability in challenging industrial environments. By effectively removing tramp metal, these pulleys not only improve product purity but also protect downstream equipment from potential damage.

Whether you're dealing with recyclables, minerals, or food products, our Magnetic Head Pulleys offer a cost-effective solution for ferrous metal separation. With customizable sizes and strengths, we can tailor our pulleys to meet your specific conveyor configurations and separation requirements.

Choose Bunting's Magnetic Head Pulleys for superior metal separation, improved operational efficiency, and enhanced product quality in your material handling processes.

Reliable Metal Separation: Efficiently removes ferrous contaminants from various materials, ensuring product purity and protecting downstream processing equipment from potential damage.

Cost-Effective Solution: Reduces equipment wear, minimizes maintenance requirements, and prevents costly machinery breakdowns by removing tramp metal during material transportation.

Versatile Performance: Adaptable to multiple industries and material types, providing consistent separation across recycling, mining, aggregate, and bulk material handling applications.

Low Maintenance Design: Engineered with robust construction and high-quality magnetic materials, offering long-term reliability and minimal operational intervention.

Enhanced Product Quality: Improves overall material quality by removing unwanted ferrous tramp, increasing the value and usability of processed materials.

Energy Efficient: Operates without additional power requirements, utilizing the natural conveying motion to achieve effective metal separation.

Customizable Options: Available in various sizes and magnetic strengths to match specific operational requirements and conveyor configurations.

Magnet Types

Permanent FerriteRare Earth

Electromagnet

Materials Handled

Suitable for bulk materials

Standard Sizes

Diameter: 168 mm to 1050 mm (6 in to 42 in)

Face Width: Custom to match conveyor belt width

Shaft sizes: To suit existing conveyor specifications

Pulley Construction

Shell: Mild steel or stainless steel

End Plates: Mild steel or stainless steel

Shaft: High-strength steel, precision machined

Bearing Options

Regreasable ball bearings

Sealed-for-life bearings

Plummer block housings

Surface Options

Plain steel

Rubber lagged (various patterns available)

Ceramic lagged for high-wear applications

Finish

Painted or unpainted (stainless steel)

Optional Features

ATEX certification for explosive environments

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.