Electromagnetic Dry Filter

| Magnet | Electromagnet |

| Strength | 3,500 & 5,000 Gauss (background field) |

| Material | Dry Fine Powders |

| Separates | Fine Iron, Paramagnetic Minerals |

Options / Features

.gif?width=300&name=bun_heimfilter_craneanimation_240424_v07%2B(1080p).gif)

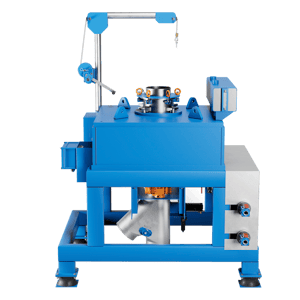

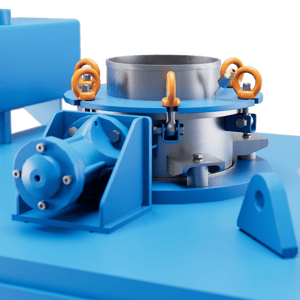

Includes a removable jib crane for easy removal of the top pole and matrix assembly for maintenance and cleanings.

%2B(1).gif?width=300&name=bun_heimfilter_airgraphics_240530_v02%2B(1080p)%2B(1).gif)

Automated back flush cleaning cycle to clean captured contaminants off the matrix.

Animation

- About

- Benefits

- Tech Specs

- Capacity

- Drawings

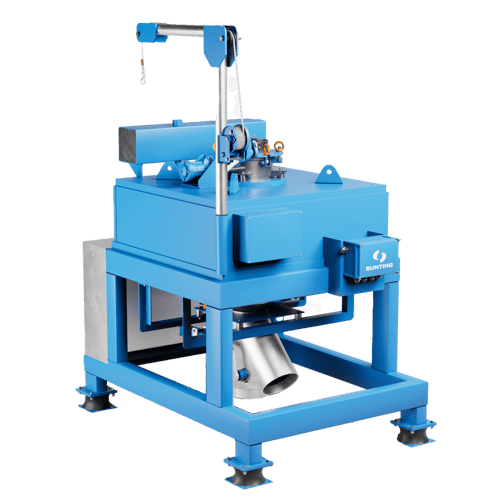

Bunting's High-Intensity Dry Electromagnetic Filter represents the cutting edge in magnetic separation technology for dry fine powders. Designed to meet the demanding needs of the recycling, battery manufacturing, and ceramics industries, this advanced system offers unparalleled performance in removing ultra fine iron and paramagnetic minerals from dry materials.

Installation and Integration

The High-Intensity Dry Electromagnetic Filter is designed for seamless integration into existing production lines. Its compact design and flexible configuration options make it suitable for a wide range of industrial setups.

Testing and Optimization

Bunting offers controlled tests on laboratory-sized filters to confirm separation capabilities and optimize performance for each customer's specific application. This ensures that each installation is tailored to meet the unique requirements of your process.

Applications

- Battery manufacturing: Purification of battery materials and removal of magnetic impurities

- Recycling industry: Processing of black mass in electric vehicle battery recycling

- Ceramics: Removal of magnetics from fine dry ceramic powders.

Key Features

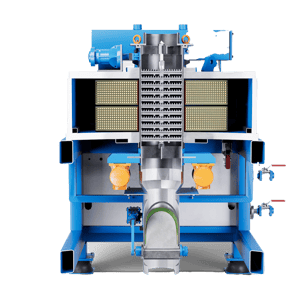

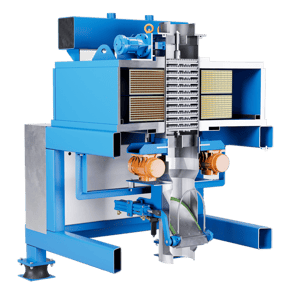

- Powerful Magnetic Field: The matrix amplifies the background magnetic field by 3-4 times to produce points of very high magnetic intensity and gradient.

- Versatile Application: Ideal for industries dealing with dry fine powders, including battery manufacturing, recycling, and ceramics.

- Multiple Models: Available in four sizes to accommodate various capacity needs, ranging from 0.15 to 0.60 m³/hr.

- Automated Operation: Fully automated using a PLC and HMI control system for precise and efficient operation.

- Energy-Efficient Design: Utilizes computer-optimized coils and an water-over-oil heat exchange system for optimal energy efficiency.

- Easy Maintenance: Features a removable jib crane for quick access to the matrix assembly, minimizing downtime.

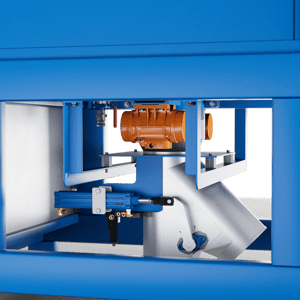

- Contamination Diverter: Incorporates a flap-style diverter valve that can be configured to suit various applications.

Technical Specifications

- Magnet Type: Electromagnet

- Magnetic Strength: 3,500 & 5,000 Gauss (background field)

- Material Processed: Dry Fine Powders

- Separation Capability: Fine Iron, Paramagnetic Minerals

Advanced Features

- Automated Cleaning: Features an automated vibration cleaning cycle with adjustable parameters via the HMI interface.

- Flexible Power Options: Available with power input options to suit global power standards.

Cooling System

- Coil immersed in oil for optimal heat dissipation

- Oil cooled via a water-over-oil heat exchange

- Optional water chiller available for closed-circuit operation

Why Choose Bunting's High-Intensity Dry Electromagnetic Filter?

- Industry-leading magnetic field strength for superior separation

- Versatile design suitable for various dry powder applications

- Energy-efficient operation

- Easy maintenance and cleaning features to minimize downtime

- Fully automated operation for consistent, high-quality results

- Backed by Bunting's 60+ years of expertise in magnetic separation technology

Experience the next level of dry magnetic separation with Bunting's High-Intensity Dry Electromagnetic Filter. Contact our team of experts today to discuss how this advanced system can optimize your production process and improve product quality.

High Magnetic Field Strength: Offers a range of background magnetic field strengths from 3,500 to 5,000 Gauss for effective separation of fine iron and paramagnetic minerals.

Applications: Used to removed fine iron and paramagnetic minerals from fine, dry powders.

Efficient Separation: Higher separation efficiency than permanent magnetic separators by generating significant background magnetic field strength, and a high-magnetic field gradient on the matrix surface.

Vibration Cleaning: Automated vibration cleaning cycle removes captured contaminants off the matrix. Cycle times can be adjusted via the HMI to suit application needs.

Energy Efficiency: Utilizes highly efficient computer-designed coils paired with an water over oil heat exchange to maintain optimal operating temperature.

Easy Maintenance: Includes a removable job crane for easy removal of the top pole and matrix assembly for maintenance and cleaning. This minimizes downtime and need for additional infrastructure.

Controlled Operation: Can be fully automated using a control system with a PLC and HMI for managing cleaning frequency and parameters.

Air Hammer: Jolts the matrix cannister during cleaning cycles.

Diverter Valve: Flap-style diverter valve with configurations to suit different applications.

Testing Facilities: Bunting offers controlled tests on laboratory-sized filters to confirm separation capabilities.

Magnet Type

Electromagnet

Magnetic Strength

3,500 & 5,000 Gauss (background field)

Materials Handled

Dry fine powders

Capacity Options

0.15, 0.33, 0.45, 0.60 m3/hr

Separation Targets

Fine iron particles, paramagnetic minerals

Industries

Battery manufacturing, recycling, mineral processing

Construction

Coil: High-efficiency computer-designed electromagnetic coil

Matrix: Magnetic (400 series) stainless steel

Casing: Steel, designed to intensify the magnetic field

Matrix Design

Expanded metal discs with staggered openings for optimal material flow

Control System

Siemens S7-1200 PLC with HMI (other options available)

Cleaning Mechanism

Automated vibration cleaning cycle with adjustable parameters

Optional Features

Adjustable magnetic field strength

Custom inlet/outlet configurations

Built-in jib for easy matrix removal and maintenance

Cooling System

Water-over-oil heat exchange for maintaining optimal operating temperature

Performance

Capable of removing very fine iron and paramagnetic minerals from dry powders

Customization

Available in various sizes and configurations to suit specific application requirements

Fill out the form below and the drawings will be emailed to you.

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.