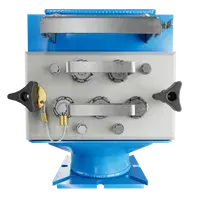

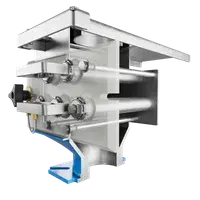

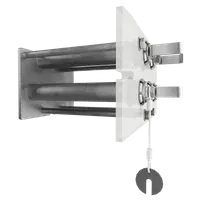

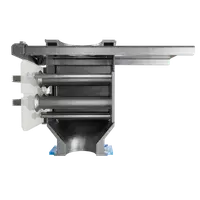

TurboGrate™ Magnetic Separator

| Magnet | Neodymium |

| Strength | 10,000 gauss |

| Material | Dry, moist |

| Separates | Ferrous |

| Std. Sizes | 200mm (8"), 300mm (12"), 400mm (16") |

Options / Features

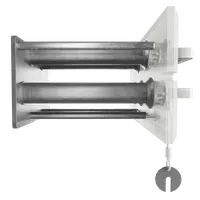

Fully adjustable speed to match flow rates

Easy maintenance, reduces downtime

Options for round or square piping available.

Video

- About

- Benefits

- Tech Specs

The TurboGrate™ Magnetic Separator is an advanced, high-performance solution designed to remove fine ferrous metal contamination from challenging materials such as powders, granules, and cohesive or greasy substances. Ideal for gravity-fed applications, this separator features a motorized rotating magnetic assembly that maintains consistent product flow while maximizing exposure to high-intensity rare earth magnets—preventing bridging, clumping, and buildup in sticky or moisture-sensitive materials.

Engineered for demanding environments, the TurboGrate™ delivers powerful magnetic separation with rare earth magnets rated at 10,000+ gauss (up to 13,000 gauss available). Its robust stainless steel construction and hygienic polished finish meet the strict standards of the food, pharmaceutical, plastics, chemical, and battery manufacturing industries. Built for reliability, the geared motor drive ensures smooth, quiet operation even in continuous-duty or shift-based processing.

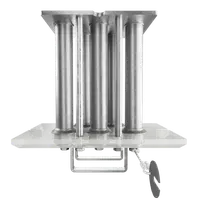

The TurboGrate™ handles product temperatures up to 80°C (176°F) as standard, with high-temp models rated to 150°C (302°F). It’s available in five standard sizes ranging from 150 to 350 mm (6"–14") inlet/outlet to accommodate a wide range of processing systems. Flexible design options include manual self-cleaning, variable-speed motors, and custom transitions for round or square chutes and pipework.

From dry powders to sticky starches, oily mixes, or abrasive materials, the TurboGrate™ Magnetic Separator ensures continuous flow, superior metal separation efficiency, and compliance with food safety and quality standards—protecting your equipment, your product, and your brand.

Metal Separation Performance

High-strength neodymium rare earth magnets capture fine and weakly magnetic ferrous contaminants, including metal dust and fragments.

Engineered for Cohesive, Hard-to-Flow Materials

Ideal for powders, granules, and materials with high fat, oil, or moisture content that are prone to bridging or clumping.

Continuous Magnetic Cleaning Action

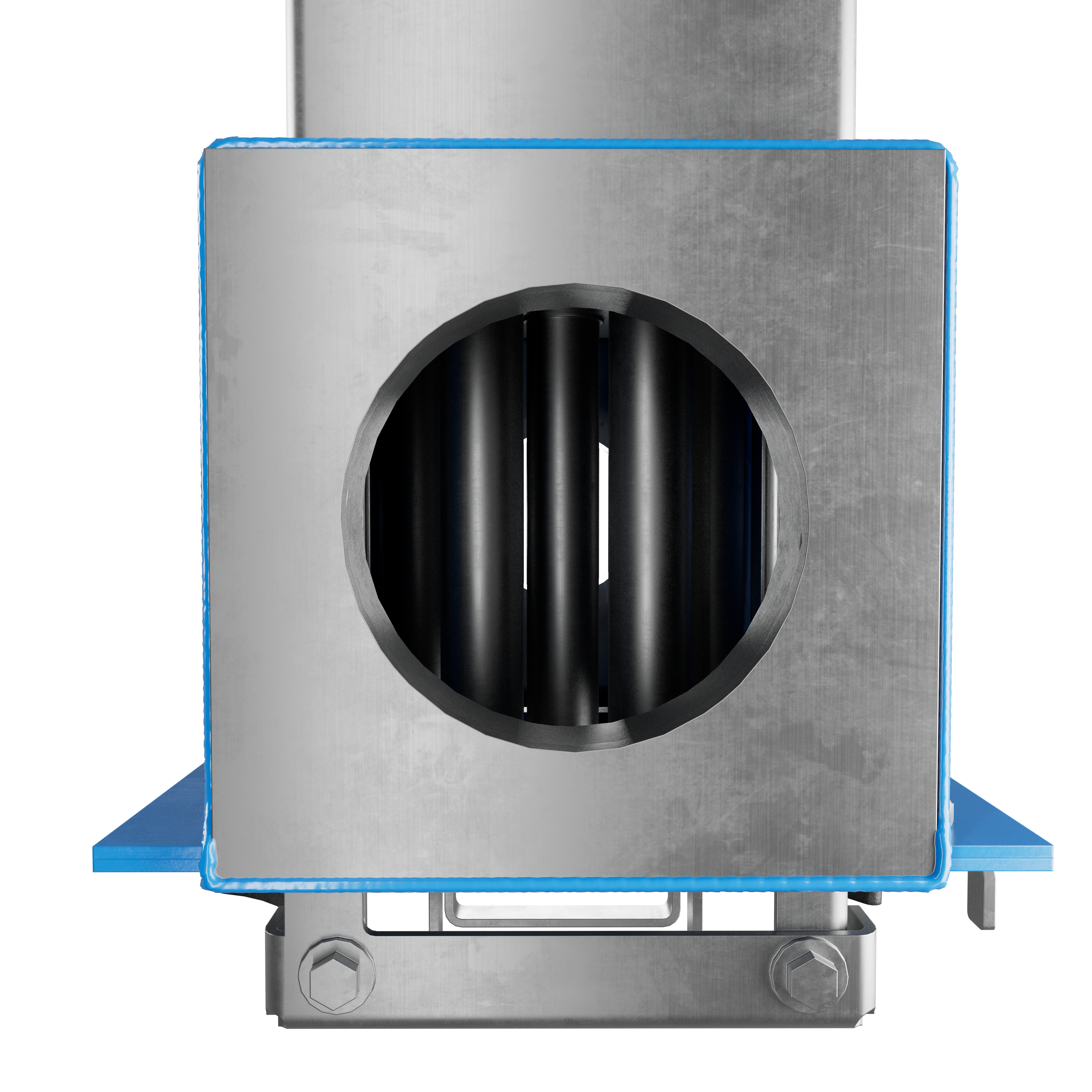

Motorized rotating magnetic rods ensure consistent product agitation and prolonged exposure to magnetic fields, maximizing separation efficiency.

Supports Product Purity and Regulatory Compliance

Enhances product quality while helping meet FDA, HACCP, and other food safety and manufacturing standards.

Protects Critical Processing Equipment

Removes ferrous metals before they reach grinders, mixers, or packaging lines—minimizing unplanned downtime and costly repairs.

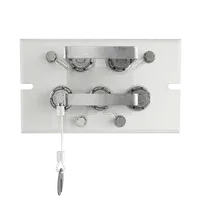

Sanitary, Hygienic Construction

Fabricated from 304 or 316 stainless steel with a polished, food-grade finish—designed for easy disassembly and cleaning in sensitive environments.

Flexible and Customizable Configuration

Available in five standard inlet/outlet sizes (150–350 mm) with options for custom transitions, variable-speed motors, and self-cleaning features.

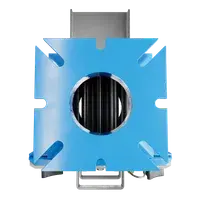

Compact, Gravity-Flow Friendly Design

Installs easily into existing vertical or inclined gravity feed systems without requiring major equipment changes.

Low Maintenance, High Uptime

Manual self-cleaning and durable drive components reduce maintenance frequency and simplify routine service.

Multi-Industry Application

Proven in food and beverage, pharmaceuticals, plastics, chemicals, and battery material processing.

Conveyance Type

Gravity free-fall applications for materials with difficult flow characteristics.

Materials Handled

Powder and granular materials prone to bridging, such as cocoa, flour, starch, baking mixes, and fatty or oily mixtures.

Standard Sizes

200mm (8"), 300mm (12"), 400mm (16") | Custom sizes available.

Inlet & Outlets

Can be custom-designed to fit specific installation requirements.

Body Options

Food grade finish is standard.

Cleaning Method

Self-cleaning option available.

Magnet Type

Powerful motorized rotating grate magnet.

Customization

Can be custom-designed to fit specific installation or application requirements.

Compliance

Meets USDA and AMS criteria as published in the NSF/ANSI/3-A 14159-1 2002 specifications.

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.