Gravity Fall Metal Detectors

![]()

Gravity free fall metal detectors are precision-engineered systems designed to detect and remove both ferrous and non-ferrous metal contaminants from free-falling bulk materials such as powders, granules, and grains. These systems operate by inspecting product flow as it falls freely under gravity through a metal detector coil, instantly rejecting contaminated material using a fast-acting separation flap or diverter valve.

Detect: Detect ferrous, non-ferrous, and stainless steel contaminants

Protect: Protect downstream equipment from metal damage

Maintain: Maintain production efficiency with minimal interruptions

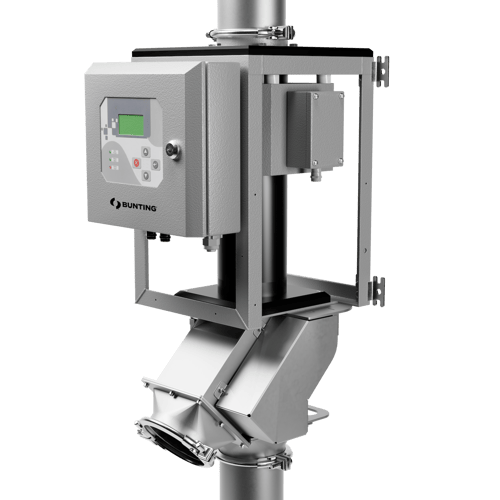

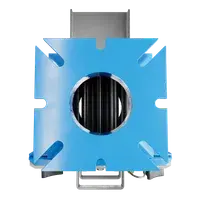

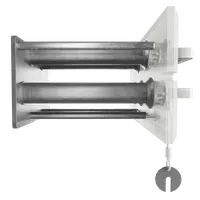

Gravity Fall Metal Detector / Separator

Applications

Food, pharmaceutical

Materials Handled

Powders, granulates, food-grade powders, pharmaceutical granules, and industrial pellets

Benefits

- High sensitivity detection of all metal types (ferrous, stainless steel, aluminum, copper, brass)

- ISO 9000 and HACCP compliance

- Hygienic open-frame design with round reject gate preventing dirt accumulation

- Network-enabled remote monitoring with flexible installation

- Explosion-proof (ATEX) versions and special configurations available

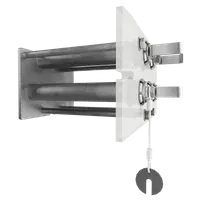

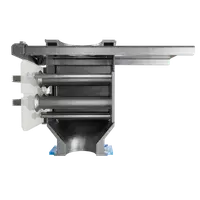

Gravity Fall Metal Detector / Separator

Applications

Food, plastics, recycling, chemical

Materials Handled

Powders, fine granular materials, pellets, granulates, bulk materials, abrasive products, and sticky materials

Benefits

- High sensitivity detection of all metal types including ferrous, stainless steel, aluminum, copper, and brass

- Compact design allows easy integration into existing production lines and confined spaces

- Digital signal processing ensures excellent detection results with minimal good product loss

- High-speed reject flap technology provides fast and accurate separation

- ATEX explosion-proof versions available for hazardous environments

- Remote control capabilities and network connectivity options

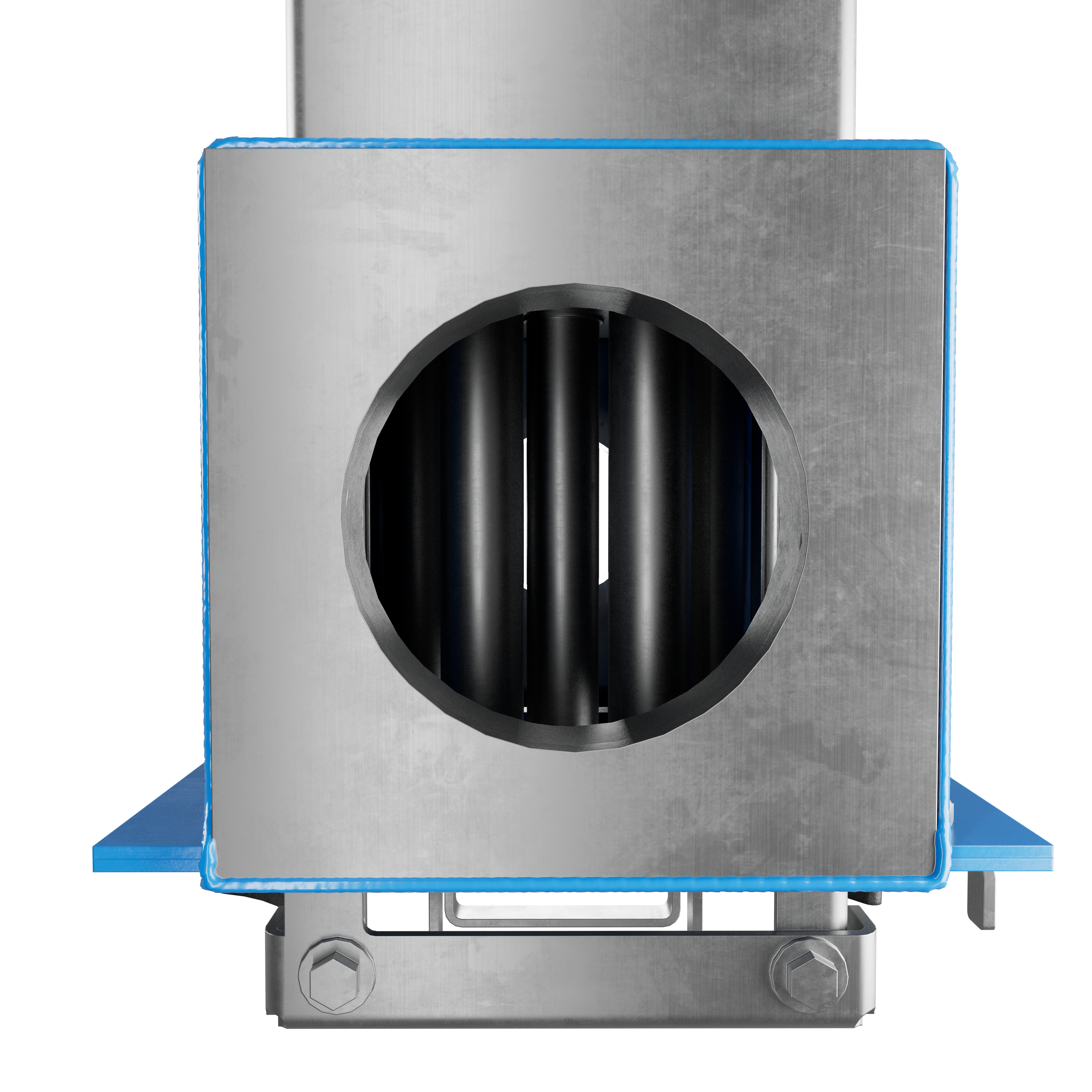

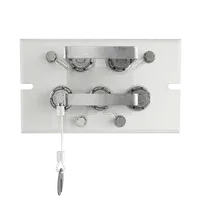

Gravity Fall Metal Detector / Separator

Applications

Plastics, recycling

Materials Handled

Plastic granulates, pellets, regrind, and fine abrasive materials

Benefits

- Detects and rejects fine metal contaminants with high sensitivity

- Handles abrasive materials without sacrificing performance

- Self-monitoring with built-in diagnostics for autonomous operation

- Compact stainless steel reject system saves space and cost

- Easy to install and retrofit using integrated mounting brackets

Other Gravity Fall Metal Detectors

Performer P

A high-sensitivity metal detector for gravity and pneumatic conveying lines. Featuring patented coil technology and advanced controls, it ensures reliable detection in compact spaces and can be installed vertically or horizontally for maximum flexibility.

Performer L

A low-profile metal detector built for gravity free-fall lines, perfect for multihead weighers and vertical bagging machines where space is tight. Its compact design, advanced controls, and powerLINE coil ensure reliable metal detection and easy integration, even in the most confined installations.

Performer R

A cost-effective, collar-style metal detector for gravity and pneumatic conveying lines, ideal for bulk materials, liquids, pastes, and slurries. Featuring high-frequency, triple-coil precision and advanced digital controls, it offers easy installation, reliable detection, and durable performance—even in demanding environments.

About

Bunting’s Free Fall Metal Detectors are precision-engineered solutions designed to detect and remove metal contaminants from free-flowing bulk materials such as powders, granules, and flakes. These systems are essential for maintaining product purity, protecting machinery, and ensuring compliance with quality standards across industries like food processing, plastics manufacturing, and recycling.

Our advanced metal detection technology identifies all types of metals—ferrous, non-ferrous, and stainless steel—within gravity-fed product streams. Once contaminants are detected, our high-speed reject mechanisms swiftly isolate and remove them without interrupting the production process. This ensures minimal product loss and maximized operational efficiency.

Key Benefits for Your Business:

- Protect Product Quality: Deliver contaminant-free products that meet the highest industry standards.

- Safeguard Machinery: Prevent costly downtime by removing harmful debris before it damages equipment.

- Boost Efficiency: Operate without interruptions thanks to automatic detection and rejection systems.

- Reduce Waste: Minimize loss of good material during the rejection process.

Whether you’re safeguarding food ingredients like flour or sugar, ensuring the quality of recycled plastics, or protecting chemical production lines, Bunting’s Free Fall Metal Detectors provide a reliable and cost-effective solution to meet your needs.

Explore our range of Free Fall Metal Detectors today to enhance your production line's safety and efficiency!

Why Choose Bunting's Performer Metal Detectors?

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.