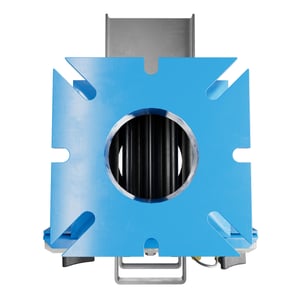

FF Drawer Magnet

| Magnet | Neodymium |

| Strength | 5,000 gauss (higher options available) |

| Material | Dry |

| Separates | Ferrous metals |

Options / Features

Rated up to 392º F (200º C) for high-temp processing.

Magnetic drawer insert removes ferrous particles with nylon wipers.

Prevents magnets from being cleaned while in-line.

Animation

- About

- Benefits

- Accessories

- Tech Specs

- Temperature Ratings

- Drawings

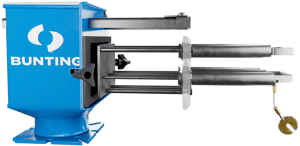

The Bunting FF Drawer Filter Magnet has been a staple in the plastics industry for over 50 years and is an essential tool for ensuring product purity and operational efficiency in the plastics industry. Specifically designed to target the removal of ferrous contaminants from plastic materials in free-fall applications, this drawer filter magnet is integral to maintaining the integrity of your products and protecting your machinery. The FF Drawer Filter Magnet features powerful rare earth magnetic cartridges that capture and hold even the smallest ferrous particles, offering superior protection against contamination in plastics processing.

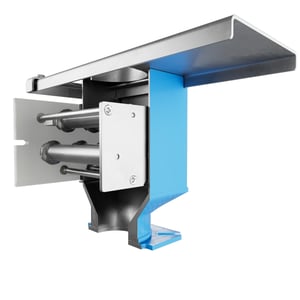

Constructed with a durable stainless steel housing, the Bunting FF Drawer Filter Magnet is seamlessly integrated into existing plastic processing lines. Its easy-to-clean drawer system allows for quick and efficient maintenance, reducing downtime and boosting productivity. This versatile drawer filter magnet accommodates various flow rates and can handle a wide range of plastic materials, making it the ideal solution for manufacturers aiming to enhance product quality and adhere to stringent safety standards. Invest in the Bunting FF Drawer Filter Magnet to optimize your plastics processing and ensure contaminant-free products.

Effective Metal Separation: The FF Drawer Magnet effectively separates and holds metal contaminants, preventing them from entering processing equipment.

Easy Cleaning: The stainless-steel dust tight welded housing allows for easy cleaning and maintenance, ensuring minimal downtime.

Durable Construction: 11 ga. housing can support symmetrical compression loads up to 10,000 lbs.

Efficient Design: Two rows of 25mm (1") tubes maximizes the magnetic circuit while allowing material to flow freely through it.

EPDM Gasket: Ethylene Propylene Diene Monomer rubber gaskets resists heat aging and compression set.

Customizable: Customization options are available to meet specific application requirements. Custom sizes increase lead time and price.

Purge Hopper - Speeds cleaning of your equipment when changing color or compound without sacrificing magnetic protection.

Dump Tube - Allows operator to completely empty the drawer housing and material hopper of plastic.

Liquid Port - Promotes quick addition of color additive into the resin. Port may also be used to hold temperature probe.

Powder Seal Kit - Provides a compression seal around the slide gate to prevent leaking of powdery materials.

Conveyance Type

Gravity flow and choke feed applications for dry, free-flowing materials.

Materials Handled

Dry, free-flowing products such as plastic pellets, powders, and granules. Effective for ferrous metals.

Standard Sizes

100, 150, 200, 250mm | 4, 6, 8, 10"

Magnetic Strength

5,000 Gauss standard, with higher options available.

Structural Integrity

Capable of supporting symmetrical compression loads up to 10,000 lbs (4.5 tonnes).

Flange Options

Universal slotted flange for compatibility with any square bolt pattern.

Material Temperatures

Standard units operate up to 80°C (176°F). High-temperature models are available for up to 200°C (392°F).

Material Contact Options

304 stainless steel for product contact areas.

Drawer Front Options

Clear polycarbonate for standard models, polysulfone for high-temperature versions.

Gasket Options

EPDM (Ethylene Propylene Diene Monomer) for standard models, Viton for high-temperature versions.

Cleaning Method

Manual cleaning with easy-to-remove drawer. Self-cleaning options available.

Magnet Type

Rare earth neodymium tube magnets.

Customization

Options available to meet specific application requirements. Custom sizes add to lead times and price.

| Size | Manual Clean | Self Cleaning | Hi-Temp Manual Clean |

|---|---|---|---|

| 100mm (4") | 176⁰ F (80⁰ C) | 302⁰ F (150⁰ C) | 392⁰ F (200⁰ C) |

| 150mm (6") | 176⁰ F (80⁰ C) | 302⁰ F (150⁰ C) | 392⁰ F (200⁰ C) |

| 200mm (8") | 176⁰ F (80⁰ C) | 302⁰ F (150⁰ C) | 392⁰ F (200⁰ C) |

| 250mm (10") | 176⁰ F (80⁰ C) | 302⁰ F (150⁰ C) | 392⁰ F (200⁰ C) |

Complete the form below and the drawings will be emailed to your inbox.

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.