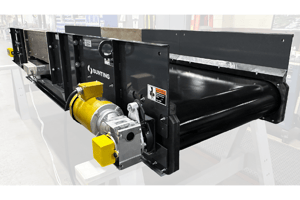

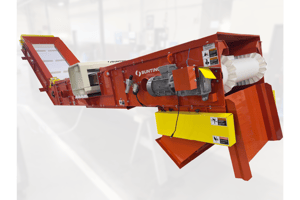

Feeder & Discharge Conveyors

Feeder and Discharge Conveyors are built to move heavy, abrasive, and jagged scrap before and after shredding. They deliver steady, controlled material flow that improves throughput, protects downstream equipment, and supports efficient metal separation.

| Material: | Heavy scrap, ferrous and non-ferrous metals, shredded material, bulk feedstock, and abrasive or jagged materials |

| Operation: | Controlled feeding into shredders and automated discharge after processing |

| Applications |

Shredding systems, scrap handling, metal recovery, recycling lines |

- About

- Benefits

- Applications

- How They Work

Bunting Feeder and Discharge Conveyors provide dependable material handling at the stages before and after shredding. They deliver consistent flow into horizontal or vertical shredders and move processed material efficiently to downstream sorting or separation equipment.

Engineered for high impact, high volume applications, these conveyors handle abrasive, jagged, and uneven feedstock with ease. They integrate smoothly with Bunting magnetic separation equipment to improve metal recovery and protect critical machinery.

Optional features such as armor plating, infeed hoppers, and containment covers enhance durability and operator safety, making these conveyors a reliable choice for continuous scrap and recycling operations.

Handle Heavy and Abrasive Scrap

Built to withstand the impact and wear of jagged, bulky, and sharp materials in demanding applications.

Provide Reliable Material Flow Before and After Shredding

Deliver a steady feed rate into shredders and remove processed scrap efficiently to maintain continuous production.

Integrate Seamlessly with Metal Separation Equipment

Work easily with magnetic pulleys, drum magnets, and eddy current separators for complete metal recovery systems.

Offer Flexible, Custom Configurations

Available in a wide range of widths, lengths, and layouts with options such as hoppers, containment covers, and armor plating.

Improve Safety and Reduce Manual Handling

Minimize lifting, spillage, and line interruptions while moving heavy materials safely and consistently.

Deliver Long Service Life with Low Maintenance

Durable frames and wear-resistant components ensure long-lasting performance with minimal downtime.

Feeder and Discharge Conveyors support smooth, safe material movement before and after shredding and are used across a wide range of scrap and recycling operations.

Typical uses include:

-

Feeding material into horizontal or vertical shredders

-

Moving processed material away from shredders for sorting or recovery

-

Discharging ferrous and non-ferrous scrap into metal separation systems

-

Integrating with magnetic separation, eddy current separators, and screening equipment

-

Handling heavy, abrasive, or irregular feedstock

By maintaining consistent material flow before and after shredding, these conveyors help increase throughput, reduce equipment wear, and support efficient recovery operations.

Feeder and Discharge Conveyors provide controlled material movement throughout the shredding and separation process.

- As feeders, they deliver a steady flow of material into the shredder, preventing surges and optimizing shredder performance.

- After shredding, discharge conveyors carry processed material to separation equipment or storage. Magnetic pulleys, drum magnets, or eddy current separators can be added to remove ferrous and non-ferrous metals as the material moves along the line.

- With heavy-duty drive systems and optional wear-resistant components, these conveyors offer continuous, reliable operation in challenging environments.

FAQ's

They handle heavy scrap, jagged materials, shredded metals, abrasive feedstock, and a wide range of bulk processing materials.

Yes. They are designed for feeding material into shredders and for transporting processed scrap to downstream separation or storage areas.

Yes. They feature reinforced frames, abrasion-resistant belts, and optional armor plating for extreme durability.

Absolutely. They work seamlessly with magnetic pulleys, drum magnets, eddy current separators, and other Bunting separation systems.

Yes. Belt widths, lengths, layouts, and optional features can be tailored to match plant requirements and material characteristics.

They reduce manual lifting, prevent material pile-ups, and provide controlled, contained movement of heavy or abrasive scrap.

Application Photos

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.