Getting Metal Contamination Out of Chocolate – Magnetic Separation and Metal Detection

Kids love it, adults love it, everybody loves it—it’s chocolate! Whether it’s a milk chocolate chip cookie, a rich, sophisticated dark chocolate truffle, or a decadent white chocolate torte, chocolate is a worldwide favorite. For the companies producing chocolate, it’s important not to let down the millions of people who look forward to chocolate as a special treat. In order to make sure their chocolate product is high quality, chocolate producers use a wide range of magnetic separation and metal detection in order to make sure all metal contamination is removed from chocolate during the production process.

All chocolate begins with cocoa beans. These beans are exceptionally hard, and the process of breaking down these beans can often result in equipment wear, or even equipment failure. This presents an enormous risk for potential metal contamination. To prevent against this, there must be a series of carefully selected and positioned magnetic separators and metal detectors to combat metal contamination in any chocolate production facility.

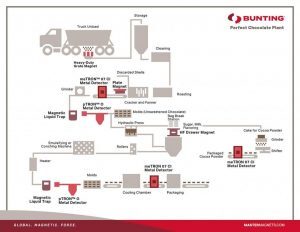

In this review, we will look at Bunting’s Perfect Chocolate Plant flowsheet in order to assess a typical chocolate manufacturing process and identify the best locations for magnetic separation and metal detection.

Stages of Ensuring Metal-Free Chocolate with Magnetic Separation and Metal Detection

Stage 1: Raw Material Delivery

Even when operating under the strictest controls, metal contamination will often still be introduced into a food manufacturing process with raw materials. Here, in the example of a chocolate plant, the delivered cocoa beans are first discharged through a heavy-duty grate magnet. This allows large tramp metal, such as nuts, bolts, and nails, to be captured. By removing larger metal at this stage, the contamination will be stopped from getting smaller and more difficult to remove. It will also prevent damage to other processing equipment downstream.

In addition to cocoa beans, other materials being delivered to a chocolate plant will also pass through magnetic separation equipment. For example, raw milk can flow through a magnetic liquid trap in order to remove any metal contamination that may be present. Magnetic separation equipment, including grate magnets, HF drawer magnets, and pneumatic inline magnets, excels at removing metal contamination from ingredients such as cocoa powder, sugar, and salt.

- Technical product information: Grate and Grid Magnets

Stage 2: Post Bean Roasting and Cracking

After cocoa beans have initially been cleaned, they are then roasted. Next, they are cracked. Once the beans have been cracked, the shells are discarded and the nuts are fed into the process. Due to the nature of the cracking process, this stage may cause equipment wear or release entrapped metal contamination. To combat this potential entry point for contamination, nuts are fed under or over the surface of a plate magnet. Here, the plate magnet attracts and holds any ferrous metal contamination.

- Technical product information: Plate Magnet

This stage in the process is also a prime location to detect any potential non-ferrous metal contamination that may be present. A metal detector such as a meTRON™ 07 CI is excellent to implement at this stage, so that material may be inspected before it passes through a grinder in the next step. Here, the combination of the plate magnet and metal detector protect the grinder from metal contamination that may have been liberated during the cracking process.

Technical product information: meTRON™ 07 CI Metal Detector

Stage 3: Post Grinding

After the grinding step has been completed, the nuts are now converted into a chocolate liquor. The grinding process is prone to introducing fine metal into the process due to natural wear of the grinder. To remove this metal contamination, the chocolate liquor is passed through magnetic separators and metal detectors before it is molded into unsweetened chocolate or passed on for further processing. At this step, chocolate processors utilize equipment specially designed for handling liquids and for installation into liquid or slurry pipelines. For example, a magnetic liquid trap may be installed to remove fine iron from liquid chocolate.

- Technical product information: Magnetic Liquid Trap

Stage 4: Cocoa Powder

Next, chocolate liquor will pass through a hydraulic press where it is split into cocoa butter and cake for cocoa powder. Cocoa cake is fed onto a grinder and screen, and the packaged cocoa powder will pass through a meTRON™ 07 CI Conveyor metal detector as a final check. Commonly, chocolate plants use air to convey cocoa powder. In this case, a pneumatic inline magnet is used.

Stage 5: Addition of Sugar

Whenever any new raw materials are added into the process, the risk of adding metal contamination will always be present as well. To combat this risk, sugar and milk flavor additives are fed through an HF Drawer Magnet. This HF Drawer Magnet will capture and hold any fine tramp ferrous metal that may be present before the new material is mixed with the cocoa butter. This ensures that the new chocolate mix will be metal-free before it passes to the rollers. Since rollers are highly susceptible to damage from such metal contamination, it is especially important that metal contamination is removed prior to material passing through the rollers.

- Technical product information: HF Drawer Magnetic Separator

Stage 6: Hot Molten Chocolate Mix

After chocolate is mixed and passed through a series of rollers, the mixture will be emulsified and then heated. Next, this molten hot mix will pass through a special magnetic liquid trap with a built-in water jacket. By circulating hot water in the water jacket, processors can ensure molten chocolate will not cool while passing through the body of the filter.

Because of the high temperature of the molten chocolate, it is important to carefully select the magnets used in the tube magnets of the magnetic liquid trap. When exposed to high temperatures, the magnetic field of certain magnets can be irreversibly damaged.

After chocolate passes through a magnetic liquid trap equipped with special high-temperature resistant neodymium magnets, the mixture will pass through a pTRON™ metal detector to detect any remaining non-ferrous metal contamination. This joint protection is a final stage prior to chocolate being placed in molds and formed into shape.

Stage 7: Final Check

Once chocolate has been fed into molds, it is then allowed to cool. The final product check comes after cooling, when the molded and formed chocolate is fed on a conveyor through a meTRON™ 07 CI Conveyor metal detector prior to packaging. After it is packaged, the metal-free chocolate will then be shipped out for sale to the millions of chocolate lovers all over the world.

Incorporating a comprehensive, multi-step metal detection and magnetic separation system is the best way to ensure a product is metal-free and prevent damage from being done to delicate processing equipment. As this blog has illustrated, the primary focus is on areas where metal is likely to be introduced (material input) or released (process equipment wear or potential failure) as part of the production process.

To learn more about how Bunting can design a comprehensive custom metal removal system for your food processing plant, Contact us Today.