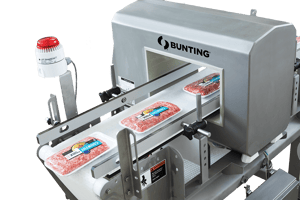

Conveyor Metal Detector

| Detects: | Ferrous, non-ferrous and stainless steel |

| Applications |

Food processing, packaging, plastics, recycling, bulk goods |

Tunnel Metal Detectors

Tunnel Metal Detectors are designed to provide high-sensitivity detection of ferrous, non-ferrous, and stainless steel contaminants in a wide range of conveyed products. Available in both one-piece tunnel style for food applications and two-piece tunnel style for industrial applications, these detectors integrate easily into existing production lines to ensure product safety, equipment protection, and compliance with quality standards.

One-Piece Tunnel Style Metal Detectors

Applications

Food processing, packaging, and ingredient handling

Materials Handled

Packaged and unpackaged products, frozen foods, baked goods, bulk powders, grains, spices, dairy, meats, and snacks

Benefits

- High-sensitivity detection of ferrous, non-ferrous, and stainless steel contaminants

- Hygienic one-piece design for easy cleaning and washdown compatibility

- Integrated system with digital signal processing for high-speed accuracy

- Supports HACCP, FSMA, FDA, USDA, and GFSI compliance

- Seamless integration with pushers, diverters, or air blast reject systems

- Low-maintenance operation with durable construction for 24/7 environments

Two-Piece Tunnel Style Metal Detectors

Applications

Plastics processing, recycling, and general manufacturing

Materials Handled

Shredded plastic, granules, pellets, bulk fiber, and conveyed product on non-metallic belts

Benefits

- High-sensitivity detection of ferrous, non-ferrous, and stainless-steel contaminants

- Split-coil design enables installation around existing conveyors without cutting the belt

- Ideal for retrofitting inspection capabilities.

- Compatible with reject systems and integrates easily into automation environments

- Corrosion-resistant construction options for washdown or industrial settings

- Supports regulatory compliance and quality assurance programs across industries

- About

- Benefits

- Applications

- How They Work

Tunnel Metal Detectors provide continuous inspection of packaged and unpackaged products as they move along conveyors or chutes. They are designed to detect ferrous, non-ferrous, and stainless steel contaminants, protecting equipment, meeting quality standards, and ensuring consumer safety.

Available in one-piece tunnel designs for hygienic food processing and two-piece split coils for plastics, recycling, and industrial use, they integrate easily into both new and existing production lines. Rugged construction and advanced digital controls make them reliable in 24/7 operations.

High-Sensitivity Detection

Identifies ferrous, non-ferrous, and stainless steel contaminants in both food and industrial products.

Hygienic or Industrial Designs

One-piece construction for food safety and washdown cleaning; split-coil versions for conveyors in plastics and recycling.

Supports Compliance & Quality Standards

Helps meet HACCP, FSMA, FDA, USDA, GFSI, and industry-specific quality assurance requirements.

Seamless Integration

Works with reject systems such as pushers, diverters, or air-blast units, and connects to plant automation controls.

Retrofit-Friendly Options

Two-piece models install around existing conveyors without cutting belts, making them ideal for upgrades.

Low-Maintenance Operation

Durable construction and advanced electronics minimize service needs, even in harsh environments.

Tunnel Metal Detectors are used in food safety, plastics, recycling, and industrial quality assurance:

-

Food Processing & Packaging: baked goods, frozen meals, dairy, meats, snacks, powders, grains, spices, and packaged ingredients.

-

Plastics & Recycling: shredded plastics, pellets, granules, resins, bulk fibers, and recycled materials moving on non-metallic conveyors.

-

General Manufacturing: bulk conveyed products and raw materials that require contaminant-free inspection.

These systems protect downstream equipment, reduce costly downtime, and help companies meet regulatory compliance and quality assurance standards across multiple industries.

- Tunnel Metal Detectors consist of a coil (one-piece or split design) positioned around the conveyor or chute and a separate control unit housed in an enclosure.

- As material passes through the tunnel, the coil scans for metal contaminants. If metal is detected, the coil sends a signal to the control unit. The system processes the signal and triggers programmed actions such as stopping the conveyor, sounding an alarm, marking the product, or activating a rejection device.

- Designed for continuous inspection, they provide fast and accurate detection in high-throughput food, plastics, recycling, and manufacturing operations.

FAQ's

A Tunnel Metal Detector is a system that inspects products as they pass through a tunnel-shaped coil on a conveyor or chute. It detects ferrous, non-ferrous, and stainless steel contaminants in food, plastics, recycling, and industrial materials to protect equipment and ensure compliance.

Tunnel Metal Detectors are used in food processing and packaging, plastics manufacturing, recycling facilities, and general industrial production. They are essential for meeting food safety regulations, improving product quality, and protecting downstream equipment from tramp metal.

They inspect packaged and unpackaged food products, frozen meals, baked goods, powders, grains, spices, dairy, meat, snacks, shredded plastics, pellets, granules, resins, and bulk fibers. Both food-grade and industrial tunnel detectors are available to match the application.

Products pass through the tunnel coil while being transported on a conveyor or chute. If a metal contaminant is present, the detector coil generates a signal that is processed by the control unit. The system then activates alarms, stops the conveyor, or triggers a rejection device to remove the contaminated product.

-

One-piece tunnel detectors are designed for food safety. They feature a hygienic frame for easy cleaning and are compatible with washdown environments.

-

Two-piece tunnel detectors are split-coil designs used in plastics, recycling, and industrial applications. They can be installed around existing conveyors without cutting the belt, making them ideal for retrofits.

Yes. Food-grade tunnel detectors are designed to help processors comply with HACCP, FSMA, FDA, USDA, and GFSI requirements. They integrate easily with reject systems to ensure contaminated products are removed from the line before reaching consumers.

Yes. Tunnel detectors can be installed on new lines or retrofitted into existing conveyors. Two-piece split-coil designs are specifically built for easy integration without requiring belt removal.

Yes. Food models are built with washdown-ready, hygienic stainless steel housings, while industrial models feature corrosion-resistant and dust-resistant construction, ensuring reliable operation in 24/7 environments such as recycling plants and plastics facilities.

Application Photos

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.