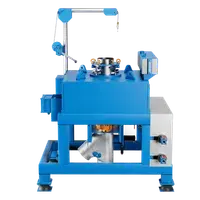

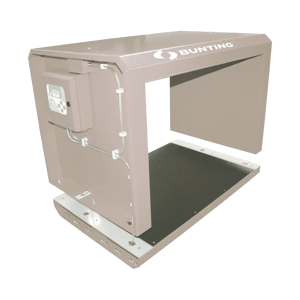

Performer Pro DT

Tunnel Metal Detector

The Performer Pro DT is a high-sensitivity tunnel metal detector designed for industrial applications, detecting tramp metal in non-metallic materials. Its divisible design allows for easy installation, while advanced digital signal processing ensures reliable performance. Flexible aperture sizes and specialized versions cater to diverse operational environments.

Options / Features

Allows for quick installation without the need to cut conveyor belts or chutes, streamlining setup in various production environments.

Proven performance in rough environments with maintenance-free, long-term operation and versions suitable for outdoor and high-temperature applications.

Includes CAN-BUS data port allowing network connection of up to 125 metal detectors, with options for remote diagnosis, parameter changes, and software updates.

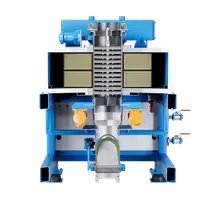

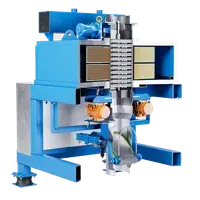

Animation

- About

- Benefits

- Tech Specs

In the demanding world of industrial manufacturing, detecting metal contaminants is crucial for maintaining product quality and protecting expensive equipment. The Performer Pro DT is designed to meet the challenges faced by manufacturers across industries including plastics, textiles, wood processing, mining, and recycling.

Advanced digital signal processing technology enables precise detection of metal particles in non-metallic materials. Unlike traditional metal detectors, this innovative system can identify a wide range of contaminants – from tiny wire fragments to larger metal components like washers, nails, and screws. Its high-sensitivity detection mechanism ensures that even the smallest metal intrusions are quickly identified and isolated.

The detector's unique divisible design sets it apart from conventional systems. Manufacturers can install the Performer Pro DT without interrupting production or cutting conveyor belts, minimizing downtime and operational disruption. This flexibility, combined with customizable aperture sizes, allows the detector to integrate seamlessly into existing production lines across various sectors.

Built to withstand harsh industrial environments, the Performer Pro DT is more than just a metal detection tool – it's a comprehensive quality assurance system. Its robust construction and advanced features help manufacturers comply with stringent industry standards, protecting both product integrity and brand reputation. By preventing metal contamination, the Performer Pro DT plays a critical role in maintaining safety, reducing waste, and ensuring consistent product quality.

Whether you're in food processing, pharmaceuticals, or heavy industrial manufacturing, the Performer Pro DT offers a reliable, efficient, and adaptable solution for metal contamination detection. It represents a commitment to excellence, safety, and continuous improvement in modern manufacturing processes.

Enhanced Product Safety: Prevents metal contamination across manufacturing processes, protecting product integrity and reducing the risk of costly recalls or equipment damage.

Operational Versatility: Adaptable to multiple industries including plastics, textiles, wood processing, mining, and recycling, providing a comprehensive metal detection solution for varied production environments.

Minimal Production Disruption: Divisible design enables quick installation without cutting conveyor systems, ensuring rapid implementation and reduced downtime during setup.

Advanced Contamination Detection: Identifies a wide range of metal contaminants including washers, nails, screws, wire fragments, and small metal particles with high precision and reliability.

Cost-Effective Quality Assurance: Reduces potential financial losses from contaminated products, equipment damage, and potential regulatory penalties through proactive metal detection.

Simplified Compliance: Helps manufacturers meet stringent industry safety standards and regulatory requirements, demonstrating commitment to product safety and quality control.

Robust Performance: Engineered to operate consistently in challenging industrial conditions, providing long-term, dependable metal detection across various environmental settings.

Detection Capability

Detects ferrous, non-ferrous, and stainless steel contaminants

High sensitivity to small metal particles in non-metallic materials

Aperture Sizes

Customizable to suit specific application requirements

Installation Options

Divisible design for easy installation without cutting conveyor belts

Suitable for conveyor systems and chutes

Control Unit

Integrated electronic control panel with LCD display

Multi-level password protection

Construction

Robust design for demanding industrial environments

IP65 protection standard (specialized versions available)

Power Supply

110/230 VAC, 50/60 Hz (standard)

Optional 24 VDC version available

Operating Temperature

Standard: 14°F to 122°F (-10°C to 50°C)

High-temperature version available

Connectivity

Relay outputs for metal detection and error signals

Optional analog output and network capabilities

Compliance

Meets CE requirements

Supports industry-specific safety standards

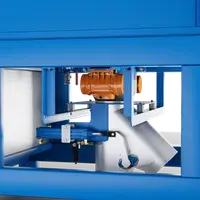

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.