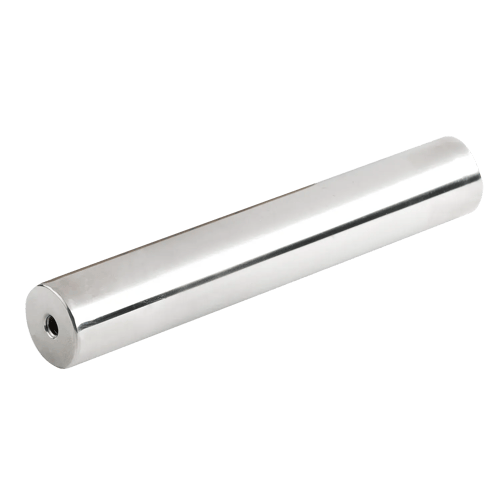

Tube Magnets

| Magnet | Neodymium, Ceramic, NUHI™ Neo Ultra High Intensity |

| Strength | Up to 10,000 gauss |

| Material | Ferrous contaminants, tramp iron, fine iron particles |

| Temperature | Up to 350ºF (170ºC) |

Options / Features

304 stainless steel for general applications and 316 stainless steel for enhanced corrosion resistance.

Available in standard and high-intensity options for superior separation and contamination control.

Available in various lengths, from 4" to 60", to fit specific application requirements.

Animation

- About

- Benefits

- Tech Specs

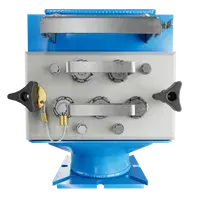

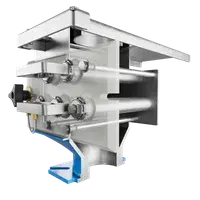

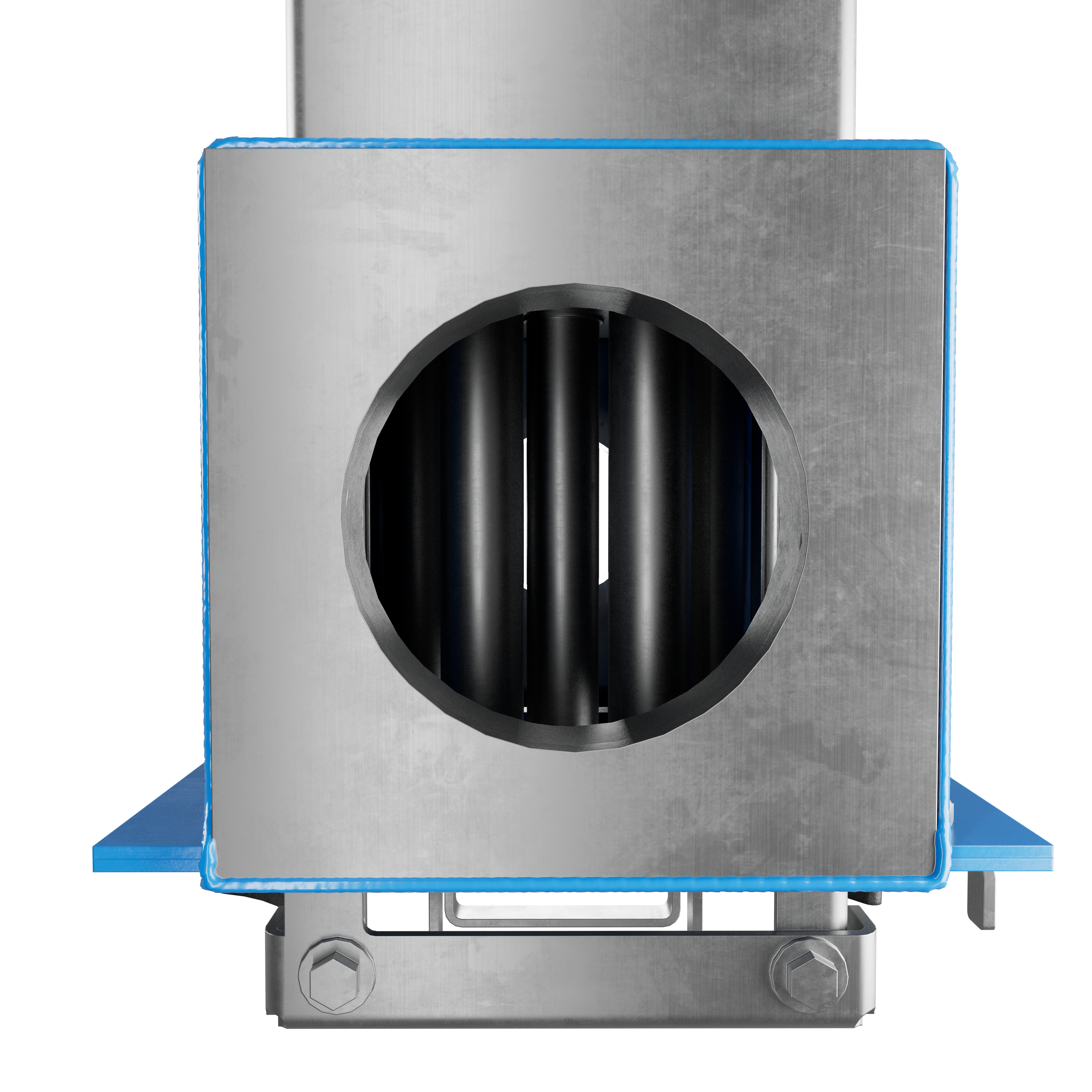

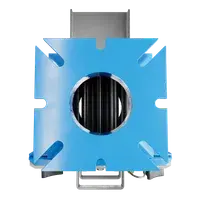

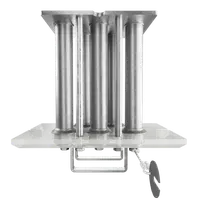

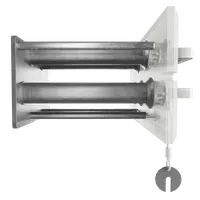

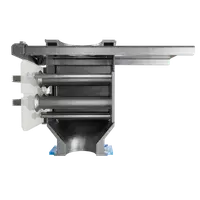

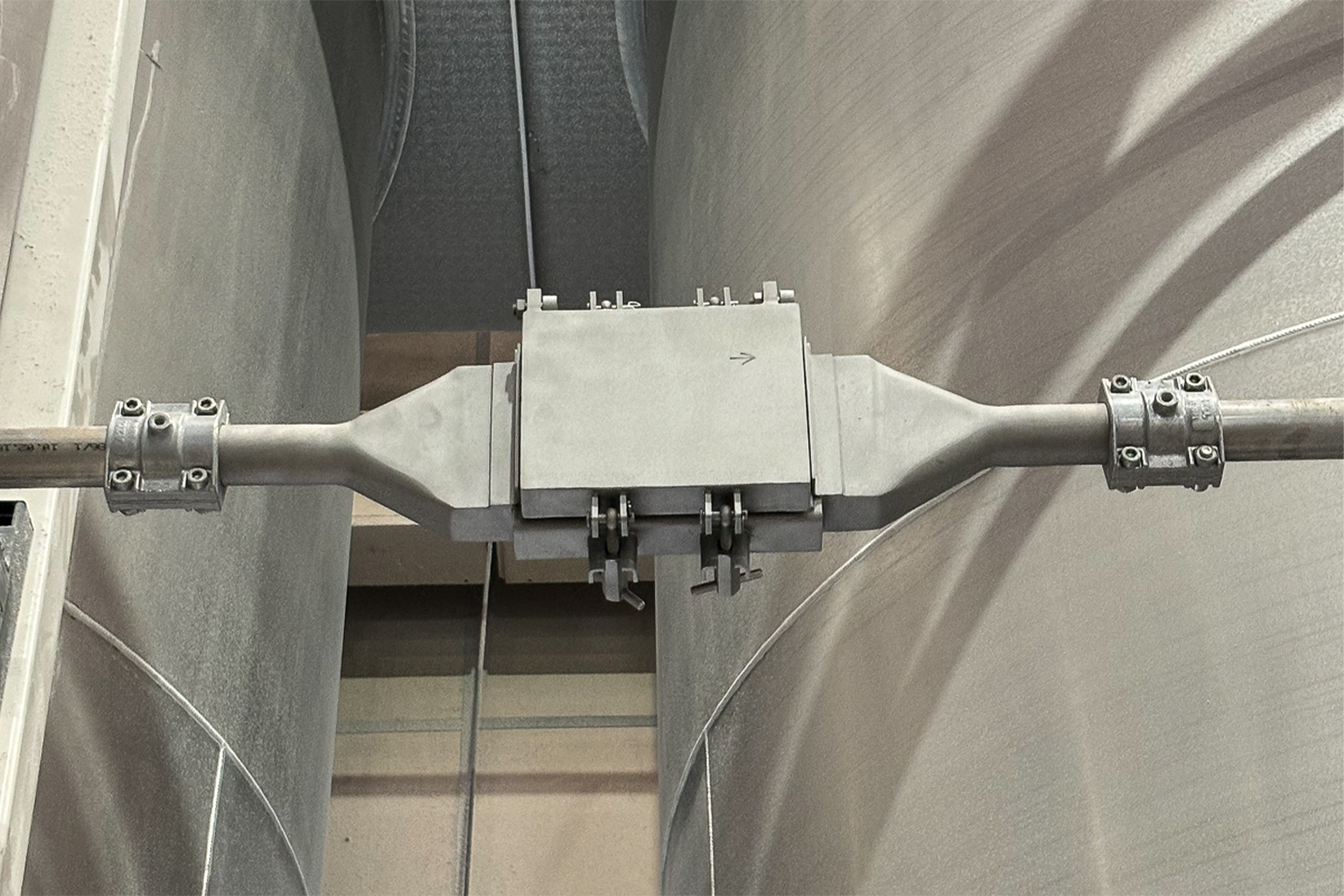

Bunting Cartridge Magnets have been a cornerstone of magnetic separation technology for decades, providing essential contamination control across various industries. These versatile magnetic separators are designed to effectively remove ferrous contaminants from dry and wet material flows, ensuring product purity and protecting valuable processing equipment. Cartridge Magnets feature powerful magnetic cores encased in durable stainless steel tubes, offering superior magnetic strength and longevity in demanding industrial environments.

Available in standard, high-intensity, and ultra-high intensity options, Bunting Cartridge Magnets cater to diverse separation needs. The NUHI™ Neo Ultra High Intensity Cartridge Magnets, featuring neodymium rare earth magnets, deliver exceptional magnetic power, capturing even the finest ferrous particles. With customizable sizes ranging from 4" to 60" (100 to 1500 mm) in length, these magnets can be easily integrated into existing production lines, hoppers, chutes, and material handling systems.

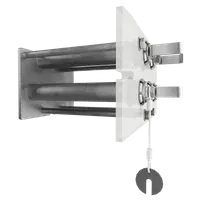

Bunting Cartridge Magnets are constructed using high-grade 304 or 316 stainless steel, ensuring durability and corrosion resistance. Their simple yet effective design allows for easy cleaning and maintenance, minimizing downtime and maximizing operational efficiency. Whether used individually or arranged in multi-row arrays, Cartridge Magnets provide a flexible solution for gravity-fed, free-fall applications across food processing, plastics manufacturing, recycling, and other industries requiring stringent contamination control.

Invest in Bunting Cartridge Magnets to enhance your product quality, protect your equipment, and meet industry standards for magnetic separation. With their proven performance and adaptability, these magnetic separators are an indispensable tool for manufacturers seeking to optimize their production processes and ensure contaminant-free products.

Contamination Control: Cartridge Magnets effectively capture and hold ferrous metal contaminants in various material flows, ensuring product purity and equipment protection.

Customizable Strength: Available in standard, high-intensity, and ultra-high-intensity options to meet diverse separation needs across industries.

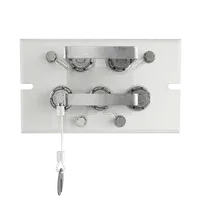

Flexible Installation: Designed for easy integration into existing systems with options for threaded holes, rods, or plain sealed end plugs.

Durable Construction: Made from high-grade stainless steel (304 or 316) to withstand harsh industrial environments and ensure long-term performance.

Size Adaptability: Offered in a range of diameters and lengths (from 4" to 60") to fit various application requirements and space constraints.

Enhanced Safety: Helps prevent equipment damage and potential hazards by removing metal contaminants from the production line.

Improved Product Quality: By efficiently removing metal particles, Cartridge Magnets help maintain high product purity and consistency standards.

Magnet Types

Standard: Ceramic

High Intensity: Neodymium

Ultra High Intensity: NUHI™ Neo

Magnetic Strength

Up to 10,000 Gauss (varies by model and magnet type)

Construction Material

Dry powders, granular materials, free-flowing products

Standard Sizes

Standard: 304 Stainless Steel

Optional: 316 Stainless Steel for corrosive environments

Tube Dimensions

Diameter: 1" (25 mm)

Length: Various options available to suit application

Temperature Range

Up to 350°F (170°C)

Magnetic Configuration

High-intensity magnetic core enclosed in stainless steel tube

Optional Features

Threaded ends for secure mounting

Custom lengths and diameters available upon request

Sanitary finish for food-grade applications

Industries

Food processing, plastics, pharmaceuticals, minerals, recycling

Applications

Hoppers, chutes, pipeline systems, gravity-fed processes

Performance

Effectively captures ferrous contaminants, tramp iron, and fine iron particles

Customization

Can be arranged in various configurations (e.g., grates, grids) to suit specific application requirements

Certification

Food-grade options available meeting FDA and USDA standards

Application Photos

-0476-200h.png)

-0506-200h.png)

-0471-200h.png)

-0470-200h.png)

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.