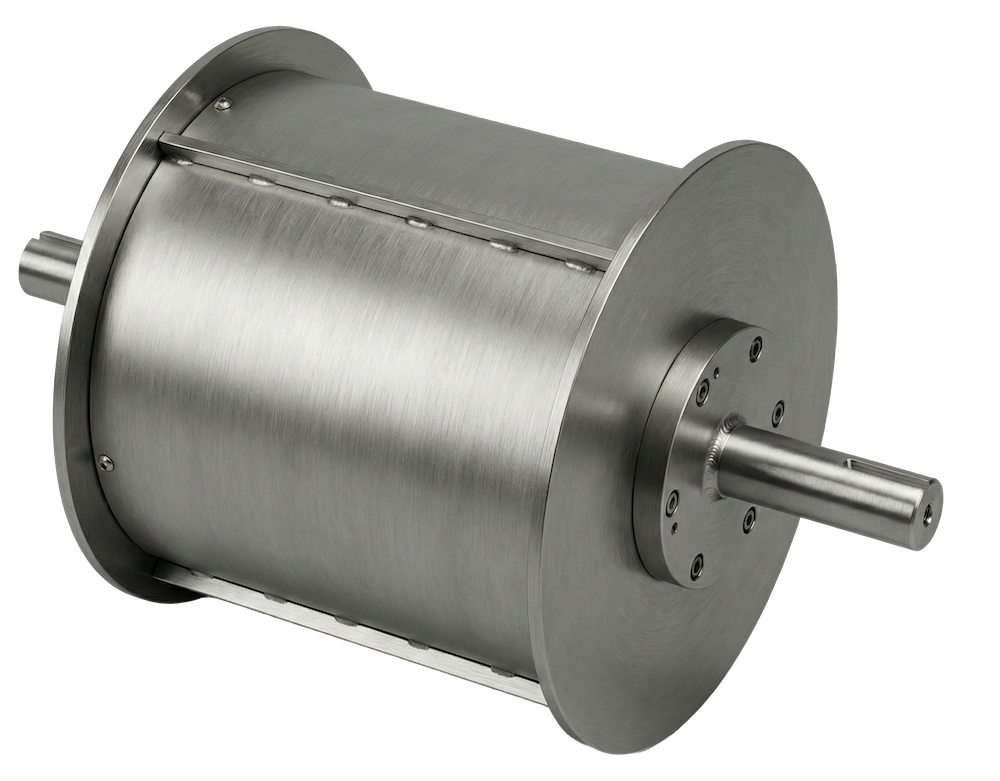

Permanent Drum Magnets

| Magnet | Ferrite, Neodymium |

| Materials | Dry |

| Conveying | Gravity, Belt, Screw, Vibratory Feed |

| Separates | Ferrous tramp |

Options / Features

For removing smaller, weakly magnetic particles

Flips the ferrous metal to reduce product entrapment.

Drums can be supplied with or without housing

Animation

- About

- Benefits

- Tech Specs

Industries: food processing, plastics, recycling, grain and milling, powder and bulk solids, aggregates, mining, minerals, ceramics

The Drum Magnet by Bunting is a high-efficiency magnetic separator designed to remove ferrous metal contaminants from a variety of product streams. This separator ensures product purity and protects processing equipment from potential damage.

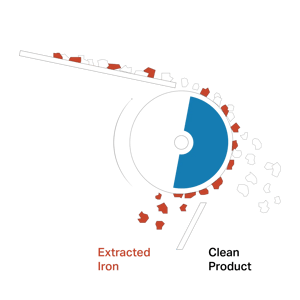

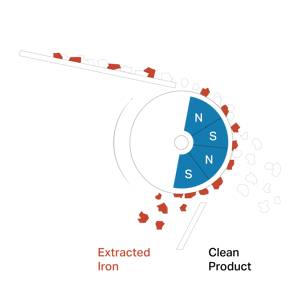

These magnets continuously capture and discharge ferrous contaminants without interrupting product flow. As material passes over the drum, magnetic particles are attracted and held to the drum's surface (radial pole design), while non-magnetic material flows freely to the discharge point. Cleats on the drum assist in sweeping the captured metal out of the magnetic field, ensuring continuous self-cleaning operation.

By integrating the Drum Magnet into your processing line, you enhance product quality, ensure compliance with industry standards, and extend the lifespan of your equipment.

Continuous, Automated Operation

Eliminates the need for manual separation or downtime—ideal for high-volume, 24/7 operations.

Reduced Equipment Wear and Maintenance

By removing ferrous metals upstream, drum magnets protect shredders, grinders, screens, and other downstream equipment from damage and costly repairs.

Increased Product Purity

Ensures cleaner output by effectively separating even weakly magnetic or fine ferrous contaminants.

Energy-Free Magnetic Power

Fully permanent magnet systems require no electricity to operate, lowering operating costs and simplifying integration.

Flexible for Any Application

Available in a range of diameters, widths, magnetic strengths, and field configurations (axial or radial) to match your specific material and flow characteristics.

Low Maintenance and Long Lifespan

With no moving internal parts and wear-resistant components, Bunting Drum Magnets offer years of reliable, maintenance-light service.

Designed for Harsh Environments

Built tough to handle abrasive, dusty, or moisture-prone materials commonly found in recycling, mining, and plastics processing environments.

Precision Separation with Adjustable Splitter

Customize the split point between magnetic and non-magnetic fractions for more efficient recovery and minimal product loss.

Advantages Over Electromagnetic Options

- No Power Required: Fully permanent magnetic design

- Low Maintenance: No cooling systems, coils, or control panels to manage

- Long Service Life: Field strength does not degrade over time

Magnet Type

Ferrite

High Intensity: Rare Earth (Neodymium)

Magnetic Field Configuration

Axial: Polarity runs along drum width

Radial: Poles run vertically down the drum

Drum Diameter

Up to 1500mm (60")

Drum Width

Up to 2400mm (96")

Shell Material

Non-magnetic stainless steel

Magnetic Arc

120-degree to 190-degree

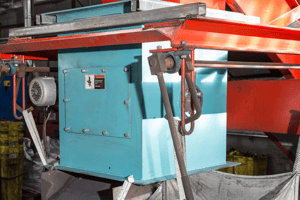

Application Photos

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.