Plate Magnets

| Magnet | Neodymium, ceramic |

| Material | Dry powders, moist, clumpy, or abrasive materials |

| Separates | Ferrous |

Types / Options

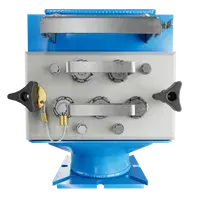

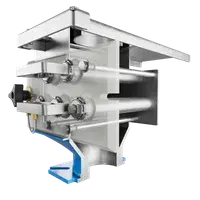

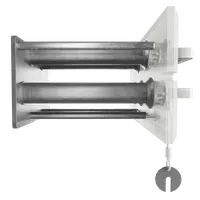

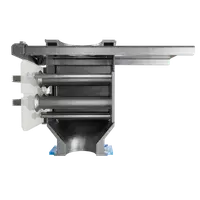

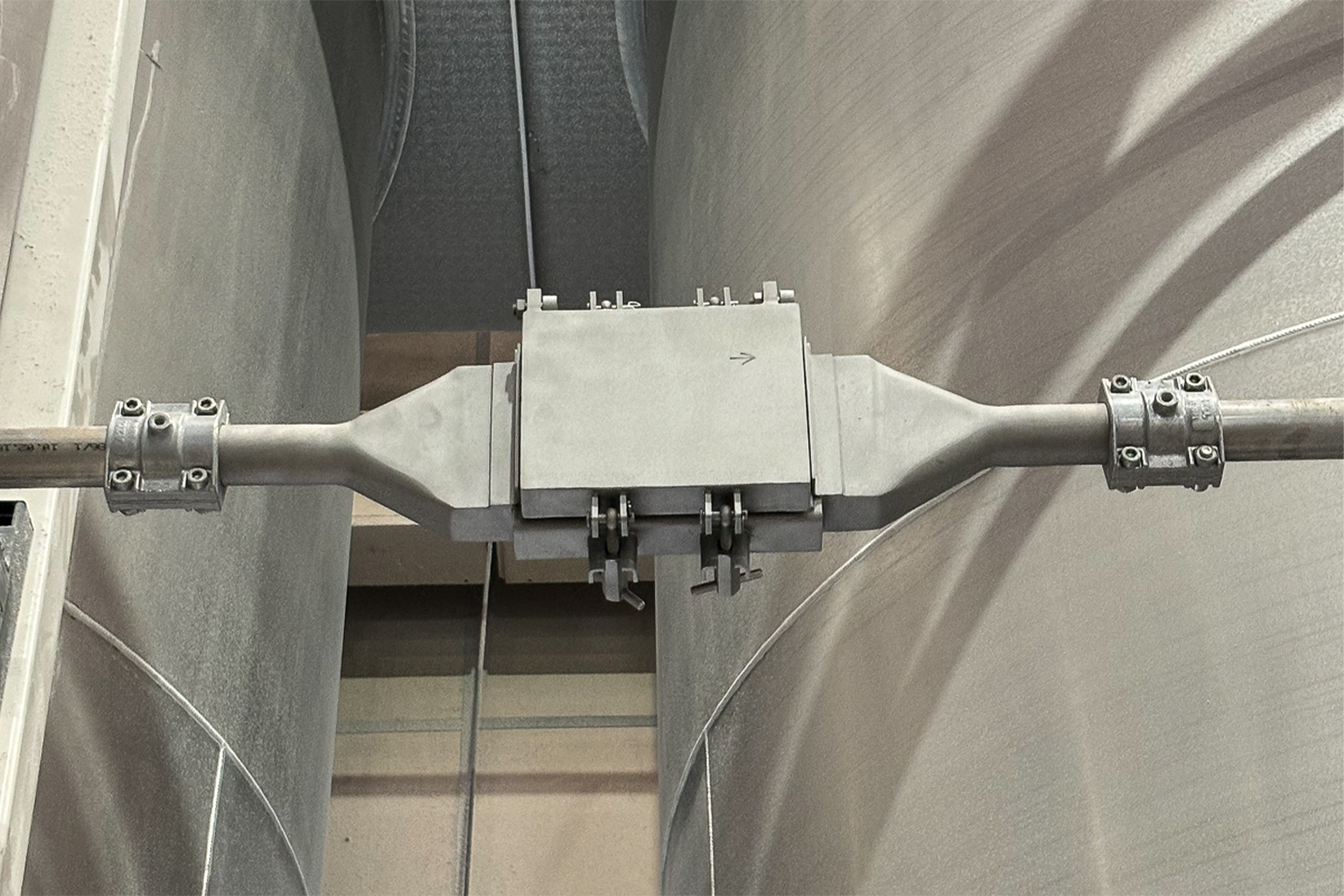

The stainless steel housings mount easily to enclosed spouting or directly on processing equipment.

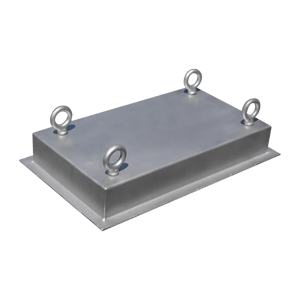

Designed to be suspended above open conveyors to remove ferrous objects and fines

Food, sanitary, and USDA finishes available to fit your production safety regulations.

Animation

- About

- Benefits

- Tech Specs

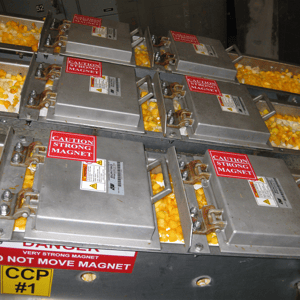

Plate Magnets are essential tools for effective metal separation in a variety of industrial applications. Designed to capture ferrous contaminants from bulk materials, these magnets play a crucial role in maintaining product quality and protecting processing equipment from damage caused by metal debris.

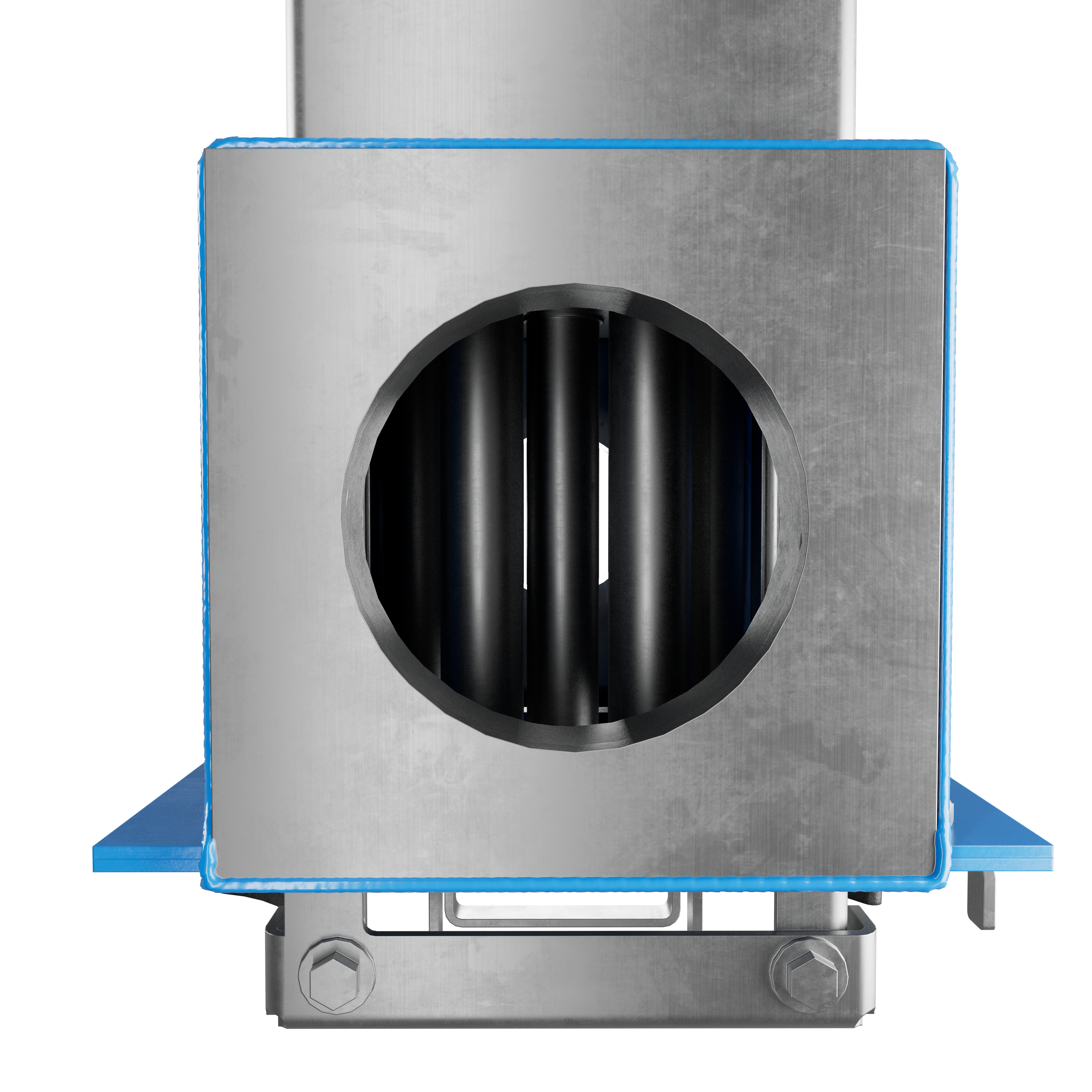

Constructed from high-quality materials, Plate Magnets are available in both Ceramic and Rare Earth magnet options, allowing users to choose the right strength for their specific needs. With magnetic strengths of up to 10,000 gauss, these magnets ensure efficient removal of tramp iron and ferrous particles from dry powders, moist materials, and clumpy substances.

Plate Magnets are particularly versatile, making them suitable for a range of industries including food processing, plastics manufacturing, ceramics, and mining. They can be installed in various configurations - such as suspended above conveyor belts or integrated into chutes - ensuring seamless operation within existing systems.

One of the key advantages of Plate Magnets is their ease of maintenance. Many models feature hinged designs that allow for quick and straightforward cleaning, minimizing downtime and ensuring consistent performance. The durable construction, often made from stainless steel, guarantees longevity and reliability even in demanding environments.

Whether you’re looking to enhance product safety, improve operational efficiency, or comply with industry regulations, Plate Magnets provide a reliable solution for ferrous metal separation.

Powerful Magnetic Field: Plate Magnets offer up to 10,000 Gauss strength, ensuring effective capture of ferrous contaminants from various materials.

Versatile Applications: Suitable for gravity-fed systems, pneumatic conveying, and conveyor belts, making them adaptable to diverse industrial needs.

Easy Installation: Standard installation kits include pre-drilled hinges and latches, allowing for quick and simple mounting in chutes or above conveyors.

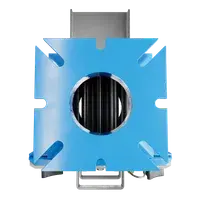

Efficient Design: Tapered magnetic face prevents contaminant wipe-off in rapid product flow, enhancing separation effectiveness.

Customizable Options: Available in 100 - 1500mm (4 to 60") widths and magnetic strengths (ceramic or rare earth) to suit specific production requirements.

Easy Cleaning: Hinged plates swing out for quick and efficient cleaning, minimizing downtime during maintenance.

Durable Construction: Made with 300 series stainless steel (316 available) for long-lasting performance in demanding industrial environments.

Compliance: Food-grade and USDA-compliant finishes are available to meet stringent production safety regulations.

Abrasion Resistance: Optional replaceable wear face available for applications involving abrasive materials, extending the magnet's operational life.

Flexible Configuration: Multiple types available (Standard, Plate Housing, Suspended) to accommodate different material handling scenarios and space constraints.

Magnet Types

Ceramic

Rare Earth (Neodymium)

Magnetic Strength

Up to 10,000 Gauss (for food-grade applications)

Materials Handled

Powdery, moist, clumpy, or abrasive materials

Standard Sizes

Width: 100 - 1500mm (4 to 60") (custom sizes available)

Construction Material

Standard: 300 series stainless steel

Optional: 316 stainless steel for specific requirements

Face Design

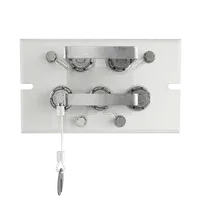

Tapered step face to prevent product wipe-off in rapid flow

Mounting Options

Hinged plates for easy cleaning

Installation kits with pre-drilled hinge and latch

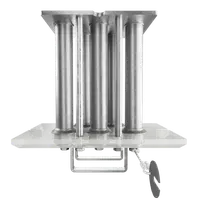

Recommended Installation

30° to 60° inclines for optimal trapping of contaminants

Applications

Chutes, above conveyors, below conveyor drive pulleys

Applications

Hoppers, chutes, pipeline systems, gravity-fed processes

Configurations

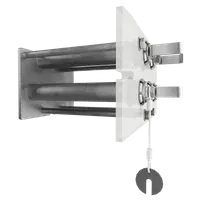

Standard Plate Magnets

Plate Housing Magnets

Suspended Plate Magnets

Application Photos

-0476-200h.png)

-0506-200h.png)

-0471-200h.png)

-0470-200h.png)

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.