Grate Magnets

| Magnet | Neodymium, Ceramic, NUHI™ Neo Ultra High Intensity |

| Strength | Up to 10,000 gauss |

| Material | Dry powders, granular materials, free-flowing products |

| Separates | Ferrous contaminants, tramp iron, fine iron particles |

Options / Features

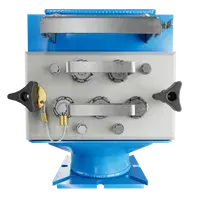

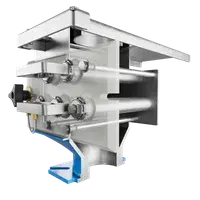

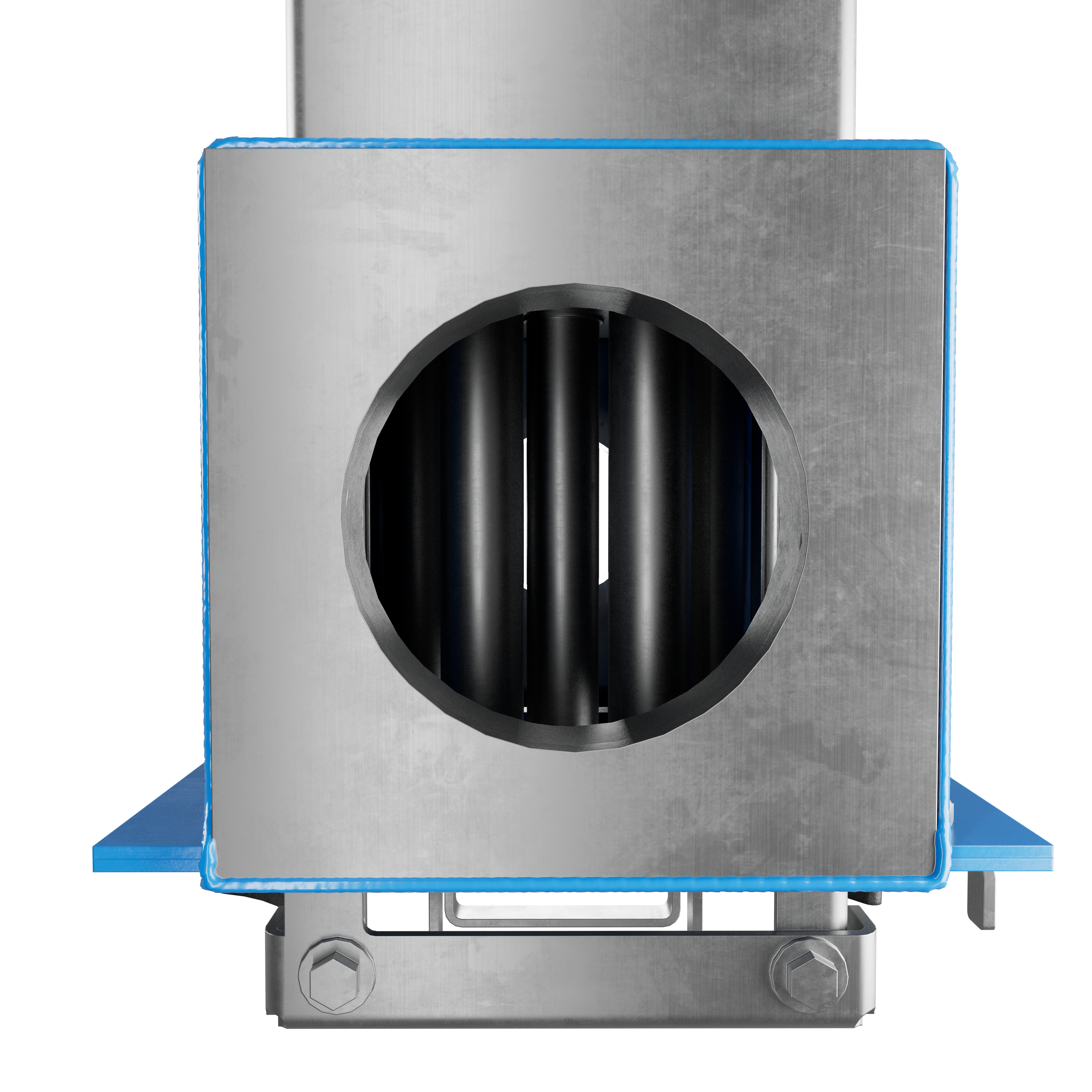

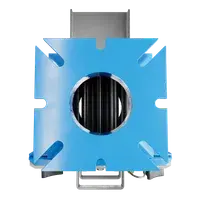

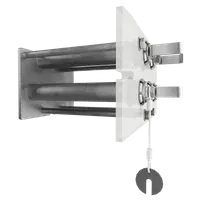

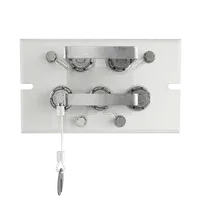

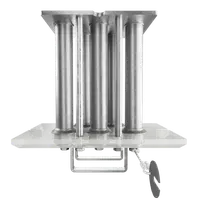

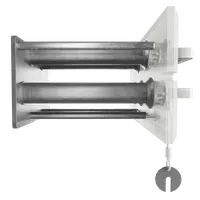

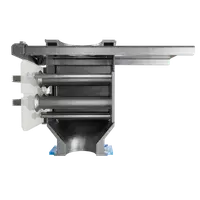

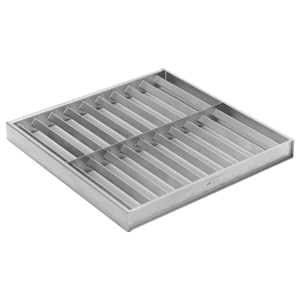

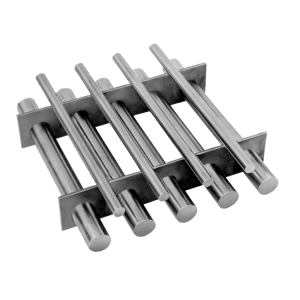

1" round cartridges, available in round and rectangular arrays.

1 ½” square tubing made from sturdy 304 Stainless Steel welded to frame with rigid channel side members.

Prevent bridging and improve separation efficiency by selecting a grate with angular or rod baffles.

Animation

- About

- Benefits

- Tech Specs

- Download

Grate Magnets have been a cornerstone in material processing industries for decades, serving as an essential tool for ensuring product purity and operational efficiency across various sectors, including food processing, plastics manufacturing, and mineral handling. Specifically designed to remove ferrous contaminants from free-flowing dry materials in gravity-fed applications, these magnetic separators are integral to maintaining product integrity and protecting valuable processing equipment.

Grate Magnets feature powerful magnetic tubes, available in ceramic, rare earth, or high-intensity neodymium options, that effectively capture and hold ferrous particles of various sizes. The strategic arrangement of these magnetic tubes creates a high-density magnetic field, ensuring thorough separation even for fine iron contaminants that might otherwise escape detection.

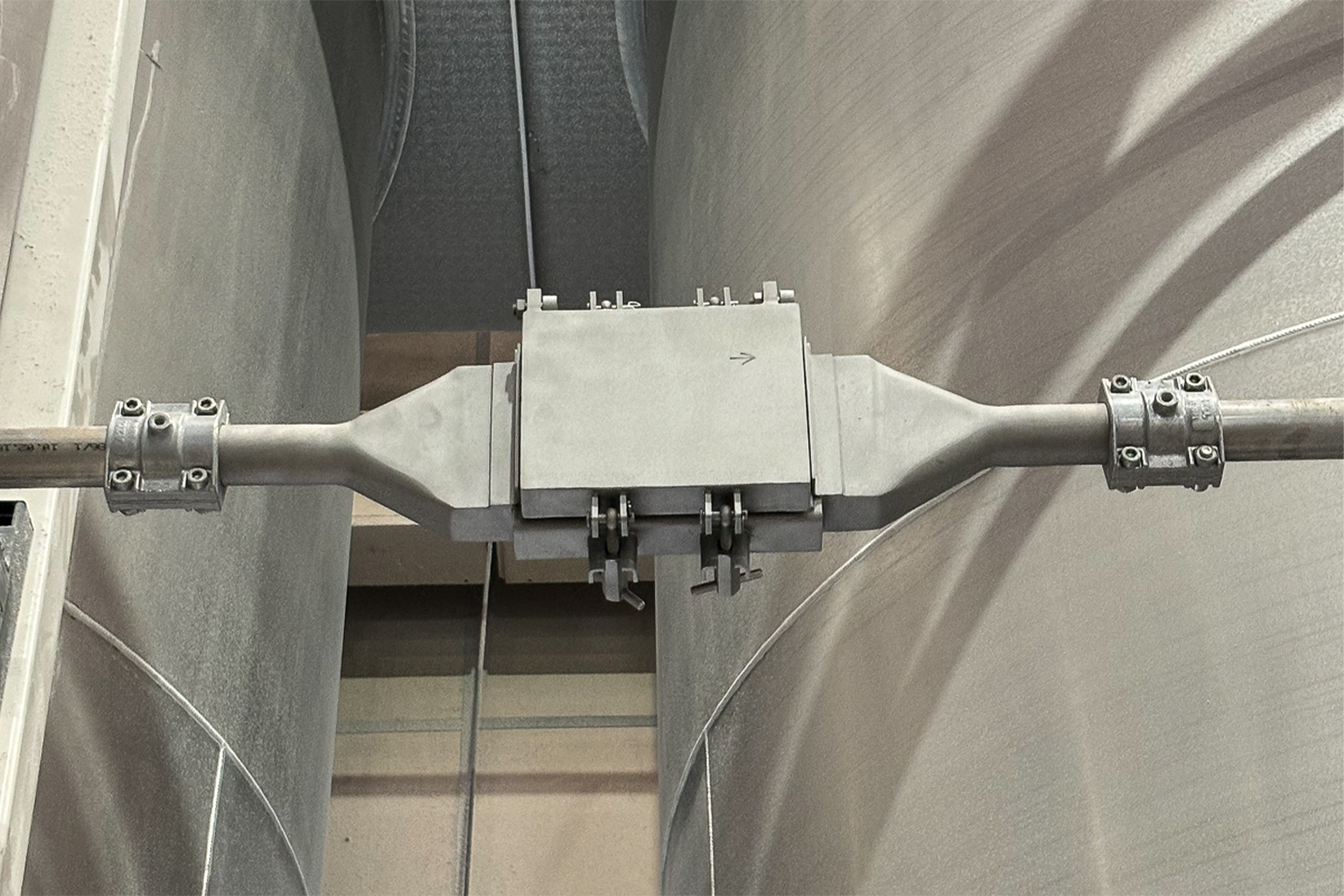

Constructed with durable stainless steel frames, Grate Magnets are designed for easy installation in hoppers, chutes, and bins, seamlessly integrating into existing processing lines. Their versatile design allows for customization to fit various shapes and sizes of processing equipment, making them adaptable to a wide range of industrial applications. The simple yet effective cleaning process involves removing the grate from the product stream and wiping the magnetic tubes clean, minimizing downtime and maintaining consistent performance.

Grate Magnets offer a cost-effective solution for manufacturers aiming to enhance product quality, comply with safety regulations, and protect downstream equipment from damage caused by metal contamination. Invest in Grate Magnets to optimize your material processing operations and ensure the delivery of contaminant-free products to your customers.

Powerful Magnetic Separation: Grate Magnets and Magnetic Cartridges effectively remove ferrous contaminants from bulk materials, ensuring product purity and equipment protection.

Versatile Installation: Easily installed or laid inside hoppers, pits, chutes, housings, and bins, providing flexible solutions for various applications.

Customizable Strength: Available with neodymium rare earth, ceramic, or NUHI™ Neo Ultra High-Intensity magnets, allowing selection of optimal magnetic strength for specific needs.

Durable Construction: Made from 304 or 316 stainless steel, ensuring longevity and resistance to wear in demanding environments.

Easy Maintenance: Designed for quick access and removal, facilitating easy cleaning and minimizing production downtime.

Size Flexibility: Offered in various sizes and configurations, from 4" to 60", to fit a wide range of application requirements.

Temperature Resistant: High-temperature options are available and rated for use up to 350°F without permanent magnet loss.

Industry Compliance: Available in food, sanitary, and USDA finishes, meeting stringent industry standards and regulations.

Enhanced Material Flow: Heavy-duty options feature designs that minimize bridging and product build-up, which are ideal for challenging materials and high flow rates.

Optimized Performance: Engineered to balance magnetic reach-out and holding force, ensuring efficient contaminant capture across various product streams.

Magnet Types

Standard: Ceramic

High Intensity: Neodymium

Ultra High Intensity: NUHI™ Neo

Magnetic Strength

Up to 10,000 Gauss (varies by model)

Materials Handled

Dry powders, granular materials, free-flowing products

Standard Sizes

Width: 4" to 60" (10 cm to 150 cm)

Custom sizes available upon request

Construction

Tubes: 1" diameter

Frame: 304 stainless steel (standard), 316 stainless steel available for corrosive environments

Magnetic Configuration

Multiple high-intensity magnetic rods arranged in a grid pattern

Temperature Range

Up to 350°F (170°C)

Optional Features

Tapered step face for improved product flow

Angled baffles to direct material over magnetic rods

Self-cleaning options available for specific models

Industries

Food processing, plastics, pharmaceuticals, minerals, recycling

Applications

Gravity-fed systems, chutes, hoppers, bins

Performance

Capable of capturing ferrous contaminants, tramp iron, and fine iron particles

Customization

Available in round, square, and rectangular configurations to suit various applications

Fill out the form below to access the specification guide:

Talk to an Application Engineer

Not sure what you need? Let’s talk through your application and identify the right solution.

Application Photos

-0476-200h.png)

-0506-200h.png)

-0471-200h.png)

-0470-200h.png)