Hump Magnets

| Magnet | Ferrite or Neodymium |

| Material | Dry |

| Conveying | Gravity Free-Fall, Moderate Positive and Negative Pressures |

| Separates | Ferrous |

Options / Features

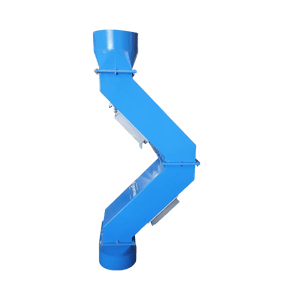

Used where Hump Magnets will not fit because of height restrictions.

Pneumatically controlled self-cleaning models reduce downtime and permit remote or automated operation.

For round, square, or rectangular spouting, available to fit any application.

Animation

- About

- Benefits

- Tech Specs

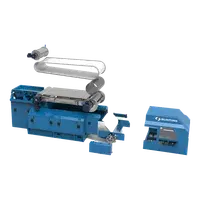

The Bunting Hump Magnet is a trusted solution for high-volume product flow applications, designed to ensure product purity and protect processing equipment across industries such as plastics, food processing, recycling, and more. Featuring a unique hump-shaped design, this magnetic separator effectively removes ferrous contaminants from free-flowing materials like powders, granules, and fibrous substances. Its angled construction directs product flow into the powerful magnetic field while breaking up clumps and preventing material bridging, ensuring optimal separation efficiency.

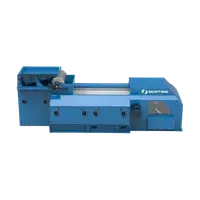

Constructed with durable stainless steel or mild steel housing, the Bunting Hump Magnet is built to withstand demanding industrial environments. Available in a variety of configurations—including the classic hump style, half-hump style for height-restricted areas, and self-cleaning models for automated operation—this separator offers unmatched versatility. The self-cleaning option minimizes downtime by automating contaminant removal, enhancing operational efficiency and productivity.

As a standard feature, Bunting Hump Magnets come equipped with metal-detectable gaskets and grommets, ensuring that any potential contaminants are easily identified during production. This added safety measure enhances compliance with industry standards and provides peace of mind for manufacturers. Whether handling fluffy materials like plastic regrind or stringy products such as potato shreds, the Hump Magnet ensures superior contaminant capture while maintaining smooth product flow. Invest in the Bunting Hump Magnet to safeguard your processes, improve product quality, and adhere to stringent safety standards.

Effective Contaminant Removal: The unique hump-shaped design ensures optimal ferrous contaminant capture from free-flowing materials, protecting downstream equipment.

Self-Cleaning Option: Available self-cleaning models automate contaminant removal, minimizing downtime and enhancing operational efficiency.

Durable Construction: Built with robust materials and precision engineering, Bunting's Eddy Current Separators withstand demanding industrial environments for long-term reliability..

Versatile Design: Offered in classic hump, half-hump, and self-cleaning styles to suit various installation requirements and material flow needs.

Durable Construction: Built with robust stainless steel or mild steel housing to withstand demanding industrial environments.

Metal-Detectable Components: Standard metal-detectable gaskets and grommets enhance safety and compliance with industry standards.

Customizable: Options for custom transitions and adapters allow seamless integration into existing processing lines.

Efficient Material Flow: Angled design prevents material bridging and breaks up clumps, ensuring smooth product flow while maximizing separation efficiency.

Compliance: Meets relevant industry standards for magnetic separation equipment in various sectors including plastics, food processing, and recycling.

Magnet Types

Standard: Ferrite (Ceramic)

High Intensity: Neodymium (Rare Earth)

Materials Handled

Dry, free-flowing products

Construction

Standard: Mild Steel

Optional: Stainless Steel for food-grade or corrosive environments

Styles

Classic Hump

Half-Hump

Self-Cleaning

Sizes

Custom sizes available to suit specific application requirements

Conveying Methods

Gravity free-fall

Moderate positive pressure systems

Moderate negative pressure systems

Separation Target

Ferrous contaminants and tramp metal

Industries

Plastics, food processing, recycling

Optional Features

Easy-clean designs

Self-cleaning mechanisms

Custom inlet/outlet configurations

Applications

Vertical chutes, hoppers, and pipeline systems

Performance

Effective ferrous metal separation with minimal product flow obstruction

Customization

Tailored designs to meet specific process and space requirements

Application Photos

Want To Know More?

For more information, we encourage you to browse our website to view our extensive range of products, and to contact one of our sales representatives to discuss your specific needs and interests.