Keep Ceramic Tiles Iron Free with Magnetic Separation and Metal Detection

The ceramics industry relies on Bunting magnetic separation and metal detection products to detect and remove metal contamination from ceramic tiles. Exceptionally costly consequences can result if fine iron and iron-bearing minerals contaminate the raw material being used in tile production. When iron contamination is present, the tile will suffer visual and structural defects that greatly compromise the overall tile quality. Additionally, the tile’s surface finish will be negatively affected, as its brightness and whiteness will suffer as well. When tiles fail a final quality check, they are typically returned to be recycled. A tile that passes the initial quality check will be classed as “first quality.” These first quality tiles approximate about 95% of all tiles produced in any given plant, though this number will vary considerably between plants. At any one ceramic tile plant, an enormous number of tiles is manufactured, which means that the volume of recycled tiles is often similarly substantial.

In 2019, 503 million square meters of tiles were produced for sale. From this number, 26 million tiles were rejected and sent to be recycled. For many of these rejected tiles, they were sent back as a result of iron contamination.

Iron contamination is a familiar foe to the ceramics industry. Out of the mix of minerals that are used to produce ceramics, iron-bearing minerals such as hematite and biotite mica are frequently included. In years past, discoloration, iron spotting, and other visual flaws were masked by adding decorative decals and patterns to the tiles. However, as design trends have changed, plain white tiles have been in greater and greater demand. In a white tile, there is no room to hide—any defect caused by iron contamination is easily visible. As a result, reject and rework rates have risen, leading to rising expenses resulting from heightened labor costs, production costs, and the cost of wasted material.

Magnetic separation technology is a simple and effective solution to iron contamination.

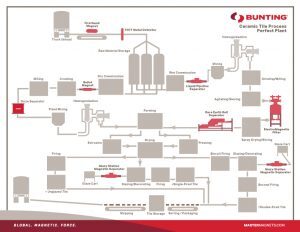

It is common for ceramic tile manufacturers to combine different designs of magnetic separators, each positioned at key points in the production process, to create a comprehensive metal removal system. A magnetic separator is able to attract and remove any magnetic particles before the ceramic is even fired. Effective removal of metal contaminants reduces reject rates and leads to reduced costs and higher profits.

This blog goes over a typical ceramic tile plant, identifying key locations and various magnetic separation designs used to remove iron from the manufacturing environment. In the flow sheet, the relative location (e.g. location RM-1) of each magnetic separator is displayed.

• Magnetic separators used in the ceramics industry

Ceramic Raw Material Infeed

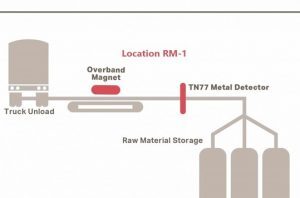

Location RM-1 – Raw Materials

Typical raw materials for ceramic include feldspar, silicon sand, zircon sand, calcium carbonate, and various clays. These materials are often delivered by road, on trucks. While many raw material suppliers use magnetic separators and metal detectors to detect and remove metal contamination before material is sent out to be transported, it is common for tramp metal to enter material in the truck itself or during the loading and discharge process.

By combining a crossbelt magnet and a rugged metal detector such as Bunting’s specially designed TN77 on the main feeder conveyer, you can ensure that raw material entering material storage silos is free of large ferrous and non-ferrous tramp metal. Common contaminants include digger teeth as well as larger screws and bolts. By removing these larger pieces of tramp metal, processing equipment such as screens and mills are protected from the serious damage that large tramp fragments can cause. Additionally, when large tramp metal is not promptly removed, it often becomes broken down into smaller pieces as a result of processing conditions. These small particles then spread throughout the raw material mix and become much more difficult to ultimately remove.

• Technical Product Information: Overband Magnets

• Technical Product Information: TN77 Metal Detector

Ceramic Body Preparation

Following storage, raw materials will pass through a dry or wet comminution process. This process then creates a ceramic slurry that contains the optimum blend of minerals and adheres to a specific particle size range. Additionally, this process will free entrapped fine iron and magnetic minerals, which produce contamination that goes on to cause structural and surface defects in the tiles post-firing.

Dry Comminution Process

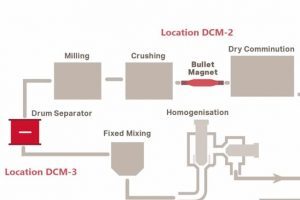

Location DCM-2 – After Mixing

Before size reduction occurs (e.g., crushing and screening), the dry mixed raw materials are potentially contaminated with smaller magnetic tramp metal, such as nails, washers, rust, and pipe-scale. This metal contamination may go on to cause costly damage to the mill and crusher. At this stage, there are two suggested magnetic separators, depending on the specific installation.

Option A--An in-line magnet, featuring a powerful rare earth magnet, is fitted into the process line where it can capture smaller tramp metal such as nails and washers before material is mixed. The centrally located magnet holds captured metal to its surface, preventing wipe-off and re-entry.

Option B—Drawer magnets, which feature one or more grids of powerful rare earth tube magnets, are commonly fitted on the infeed to mixers or to the base of silos. As material passes over the tube magnets, magnetic contamination is trapped and securely held to their surface, preventing wipe-off and re-entry.

Location DCM-3 – After Milling and Crushing

The crushing and milling process also leads to the release of entrapped magnetic minerals. Subsequently, before the material undergoes further mixing and homogenization, the dry material feed passes over a high-intensity Rare Earth Roll Magnetic Separator or Neodymium Rare Earth Drum Magnet. These high-intensity magnetic separators are able to quickly attract and automatically remove any particles that are magnetically susceptible.

Option A—A permanent Rare Earth Drum Magnet uses a stationary arc of magnets contained in a rotating non-magnetic shell to attract, hold, and separate magnetic particles. A vibratory feeder evenly feeds the dry raw material mix onto the top of the drum where it then enters the magnetic field. After magnetic particles are attracted, they are then discarded beneath the drum magnet away from the clean product.

Option B—A Rare Earth Roll Separator is designed to have a conveyor working in tandem with a high-intensity head roll that is constructed from permanent rare earth (neodymium) magnets. A vibratory feeder evenly feeds the dry raw material mix onto the belt, where it is conveyed into the magnetic field of the rare earth roll. Magnetic particles are attracted and discarded beneath the separator and away from the clean product.

Often, this is the final opportunity to capture and remove ferrous contamination before the body of material moves onto the filter press and forming.

• Technical Product Information: Drum Magnet

• Technical Product Information: Rare Earth Roll Magnetic Separator

Wet Comminution Process

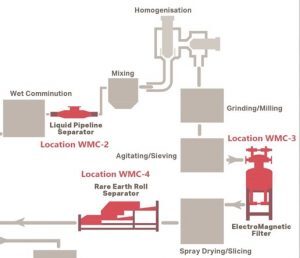

Location WMC-2 – Prior to Mixing

After water has been added to the mix of raw material, the slurry may then be conveyed through a Liquid Pipeline Magnetic Separator. This allows small, damaging tramp metal particles such as washers, nails, pipe-scale, and rust to be captured. This metal contamination would otherwise pose a serious risk of damaging the homogenizer and mixer. In a Liquid Pipeline Magnetic Separator, powerful rare earth magnets in the center of the pipe attract and hold metal contaminants, effectively removing material from the product stream and preventing re-entry.

Technical Product Information: Liquid Pipeline Magnet

Location WMC-3 – Prior to Spray Drying

The process of mixing, grinding, and milling can release entrapped magnetic particles, including both fine iron and magnetic minerals. Even though these magnetic particles are often very small, they still pose a risk. To guard against this, prior to the spray drying process, ceramic material will be passed through a high-intensity ElectroMagnetic Filter. An ElectroMagnetic Filter, designed and manufactured by Bunting-Redditch, is an automatic self-cleaning magnetic separation system that easily handles large throughputs of material. It is able to generate much higher magnetic fields compared to permanent magnets, which means it increases efficiency of separating fine iron and weakly magnetic minerals.

Additionally, because this is a self-cleaning piece of equipment, it is able to ensure that the maximum level of magnetic separation is constantly maintained. As an example, a typical cleaning cycle would be every twenty minutes depending on the amount of ferrous contamination present in the feed.

• Technical Product Information: Electro Magnetic Filter

Location WMC-4 – Cleansing Spray Dried Ceramic Particles

Before it is considered ready for the tile forming process, the wet mineral mix must be converted into spray dried particles. In spray drying, a liquid or slurry is rapidly dried with a hot gas in order to produce a dry powder. It is common for very fine iron to be introduced into the process at this step as a result of the hot air supply coming from the dryer. This results in exceptionally fine contamination, namely in iron sticking to some of the spray dried particles. This stage in the process is the final opportunity to remove magnetic particles before the tile biscuit is formed, which is critical when producing unglazed tiles.

High-intensity permanent magnetic separators, such as the Rare Earth Roll Separator and the Rare Earth Drum Magnet, are able to automatically and continuously remove both free iron and iron-contaminated spray dried particles.

Option A—A vibratory feeder evenly feeds spray dried ceramic onto the Rare Earth Roll Magnetic Separator belt, where it is then conveyed into the head roll’s magnetic field. Magnetic particles, including spray dried ceramic with iron inclusions, are attracted and then discarded underneath, away from the clean product.

Option B—A vibratory feeder evenly feeds spray dried ceramic onto the top of the Drum Magnet and into the magnetic field. As with the Rare Earth Roll Separator, magnetic particles, including spray dried ceramic with iron inclusions, are attracted and then discarded underneath, away from the clean product.

Glaze Preparation

While tile glazing is no longer applied in many ceramic tile manufacturing plants, it remains a key stage in many operations. Similar to ceramic body, glaze is composed of several different non-metallic minerals, and it is at risk of being contaminated by fine iron and magnetic minerals. During the firing process, a magnetic particle allowed to remain in the greater material will react with the heat, resulting in spotting and/or discoloration of the glaze. For this reason, the glaze must be free of contaminants.

Glazes can be many different colors, depending on the intended design, but it is often simply white. There must be great care taken when passing a colored glaze through any magnetic separators, as certain pigments can have magnetic properties.

Prior to the Glaze Cart

Many plants have their own glaze production areas, but others purchase from local producers. Similar to ceramic body, the optimum iron-separation system in this application is the high-intensity Electro Magnetic Filter. For glaze operations, the filter will operate on a batch-fed basis, treating one container of glaze at a time. To facilitate easy transport and repositioning, many Electro Magnetic Filters are mounted on moveable wheeled frames. At this stage, it is important to consider the glaze consistency, as this can affect flowability (especially if the glaze contains a gluing agent).

Electro Magnetic Filters are able to remove fine iron and weakly magnetic minerals, which reduces the risk of surface contamination and product rejects.

Location CG-5 At the Glaze Station

Carts are used to transport glaze to glazing stations, where a high strength tube magnet will be positioned either in a Liquid Pipeline Magnetic Separator or a stand-alone design configured by the customer. Here, glaze will run across the surface of the tube magnet in order to remove any fine iron before it is either poured or sprayed onto a tableware biscuit. This protection is a vital final step in ensuring iron contamination is eliminated before final firing.

• Technical Product Information: Liquid Pipeline Magnet

Optimum Magnetic Separation Reduces Rejects

It is important to fully understand the ceramic tile manufacturing process when recommending the optimum piece of magnetic separation equipment. All of the magnetic separators mentioned in this review are currently in use in ceramic production operations, and our equipment recommendations are made based on Bunting’s experience working with UK ceramic tile manufacturers. However, each manufacturing process is unique, and contacting a Bunting sales engineer will ensure you receive a specific solution for your application and your plant.