Inline Magnets Prevent Metal in Baby Food – Magnetic Separation

Last October, a German baby food producer purchased 42 stainless-steel in-line magnets from Bunting-Redditch in order to remove tramp ferrous metal from their product stream. In order to ensure maximum removal of ferrous tramp, this producer chose to install the magnetic separation products in all of their European manufacturing plants.

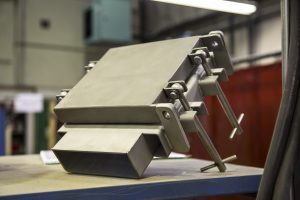

In-line magnets are ideal for quick installation in processing environments, as they easily fit into existing pneumatic (up to 15psi) or gravity-fed pipelines working to transport food. The fabricated pipe-shaped body of the in-line magnet includes ends that are easy to connect and fit into existing pipework. On one side of the body, there is a centrally mounted rare earth neodymium plate magnet. This powerful magnet efficiently captures both large and small ferrous metal contamination.

- Technical product information: In-line Magnets

Baby food has special flow considerations. It comes in many different flavors and different baby foods are tailored to fit different states of an infant’s growth. Frequently, baby food contains chunks of vegetables and meat. Because of this, it is highly important that there is no restriction to the product flow that could lead to system blockages and damage to the food. The in-line magnets were a perfect solution, as they ensure there is no restriction to the product flow.

Separating Metal Contamination in Baby Food

In this particular project, baby food passes through the body of the in-line magnet. Any ferrous or weakly magnetic materials are attracted by the plate magnet’s strong magnetic field, then captured and held against its face.

The tapered step of the plate magnet has two purposes. First, the tapered step intensifies the magnetic force of the plate magnet, making it stronger and more efficient at capturing metal contamination. Second, the tapered step provides a collection area that collects and holds metal contamination, keeping it out of the product flow and preventing re-entry.

The plate magnet will periodically need the captured metal to be cleaned off of its face. Fortunately, it is simple and quick to access the plate magnet for cleaning, as the plate magnet easily swings away from the body on reinforced hinges.

Magnetic Separation for the Food Industry

There are many different types of magnetic separators designed to be used in the food industry. In-line magnets are just one of many different pieces of equipment designed to provide custom solutions to food processors. Bunting’s range of magnetic separation equipment for the food industry includes designs for wet and dry products in addition to belt, gravity, and pneumatically conveyed food products.

For more information on magnetic separators removing contamination from baby food, or to learn how Bunting can create a custom designed metal removal system for your food processing facility, Contact Us Today.