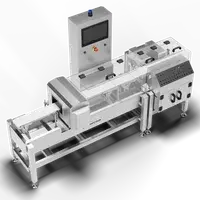

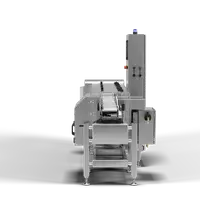

Electrostatic Separators

Bunting Electrostatic Separators provide an advanced separation solution that utilizes variations in electrical conductivity to accurately sort and recover materials. Ideal for both mineral processing and recycling, this technology delivers precise, efficient separation across a broad range of applications.

Features

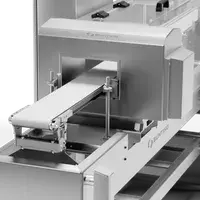

Capable of separating a wide range of materials including plastics, minerals, and metals, with particle sizes from 40 microns to 4 mm.

Delivers exceptional separation performance, enabling accurate sorting of materials based on their different electrical properties.

Features fine-tuning options for roll rotation speed, electrode positions, and applied voltage, enabling optimal separation for various materials.

Animation

- About

- Benefits

- Tech Specs

Bunting's Electrostatic Separator uses electrostatic charge to separate dry, liberated particles with different levels of electrical conductivity. This technology is commonly used in the mineral processing, plastics, and recycling industries to separate conductive materials from non-conductive (insulating) ones.

Drawing on over 65 years of experience in magnetic separation and material handling, Bunting has developed ElectroStatic Separators to address the growing need for sustainable, water-free separation methods. These systems are designed to handle a variety of materials, including minerals, plastics, and metals, supporting efforts to improve product quality, reduce waste, and recover valuable resources.

The separation process requires no water or chemicals, minimizing environmental impact. Each unit can be configured to meet specific operational needs, with control systems that support consistent, reliable performance across a range of applications.

Bunting’s ElectroStatic Separators are used in mineral processing, plastics recycling, e-waste processing and lithium ion ELV recycling where accurate, dry separation is essential. We work closely with customers to tailor solutions that align with their material recovery goals and process requirements.

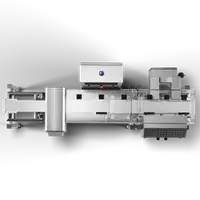

High Separation Efficiency: Allowing for precise separation of materials with different electrical properties.

Versatile Material Processing: Capable of separating a wide range of materials including plastics, minerals, and metals, with particle sizes from microns to millimeters.

Continuous Operation: Designed for non-stop processing, maximizing productivity and throughput.

Environmentally Friendly: Utilizes a dry separation process, eliminating the need for water or chemical additives, reducing environmental impact and water consumption.

Cost-Effective: Lower operating costs due to reduced waste disposal, improved material recovery, and efficient operation.

Improved Product Quality: Removes unwanted contaminants, resulting in higher purity levels and increased market value of end products.

Space-Efficient: Integrated design allows for flexible installation in various plant layouts.

Energy Efficient: Consumes less power compared to some alternative separation methods, contributing to overall energy savings.

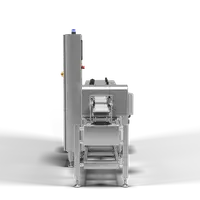

Material Processing Capabilities

- Suitable for particle sizes ranging from 40 microns to 4 mm (0.0016 inches to 0.15 inches).

- Handles a variety of materials, including plastics, minerals, and metals.

Voltage Range

- Adjustable operating voltage: up to 35,000 volts.

Roll Dimensions

- Roll diameter: 350mm (14").

Roll width

- Available in multiple configurations up to 1500mm (60").

Feed Rate

- Throughput capacity: Up to 1,000 kg/h (2,200 lbs/h) per meter width, depending on material type and particle size.

Power Requirements

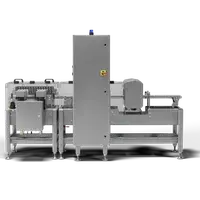

- Input power: 220-240V, single-phase.

- Components made from durable stainless steel for long-term reliability and corrosion resistance.

Control System

- Adjustable parameters for roll speed, feed rate and voltage settings.

- Local electrode and splitter positioning.

- Designed in accordance with CE standards for safety and environmental compliance.

Want to know more?

To learn more about how our separation expertise can support your operations, contact us or request a quote.